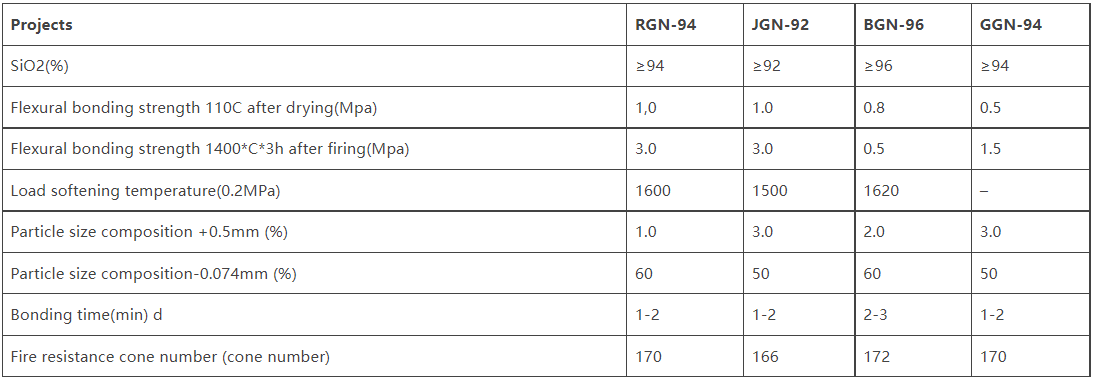

Introducing our Silica Mortar, a premium refractory product proudly manufactured by Zhengzhou Rongsheng Refractory Materials Co., Ltd., a national high - tech enterprise. This mortar is specifically designed for high - temperature industrial applications. It is made from high - purity silica powder and a binding agent, ensuring excellent performance under extreme conditions. With a silica content of 92% or more, it boasts remarkable refractoriness. Our product is certified with ISO9001 and CE, meeting international quality standards. It demonstrates great load - softening performance and workability, making it suitable for various construction scenarios. Whether it's for the repair or construction of industrial furnaces, our Silica Mortar will surely enhance the durability and efficiency of your equipment.

1. High - purity silica powder formulation guarantees excellent refractoriness. 2. With a silica content of 92% or more, it provides superior performance. 3. Exceptional bonding strength ensures a long - lasting joint. 4. Great load - softening performance can withstand high - temperature working conditions. 5. Good workability facilitates easy application in different construction scenarios. 6. Backed by a national high - tech enterprise with ISO9001 and CE certifications for quality assurance.

Our Silica Mortar is ideal for the repair and construction of various industrial furnaces such as hot air furnaces, coke ovens, and glass kilns built with silica bricks. It is suitable for industries involved in high - temperature processes, like the metallurgy, glass, and coking industries. We cater to international clients who are looking for high - quality refractory materials to improve the performance and lifespan of their equipment.