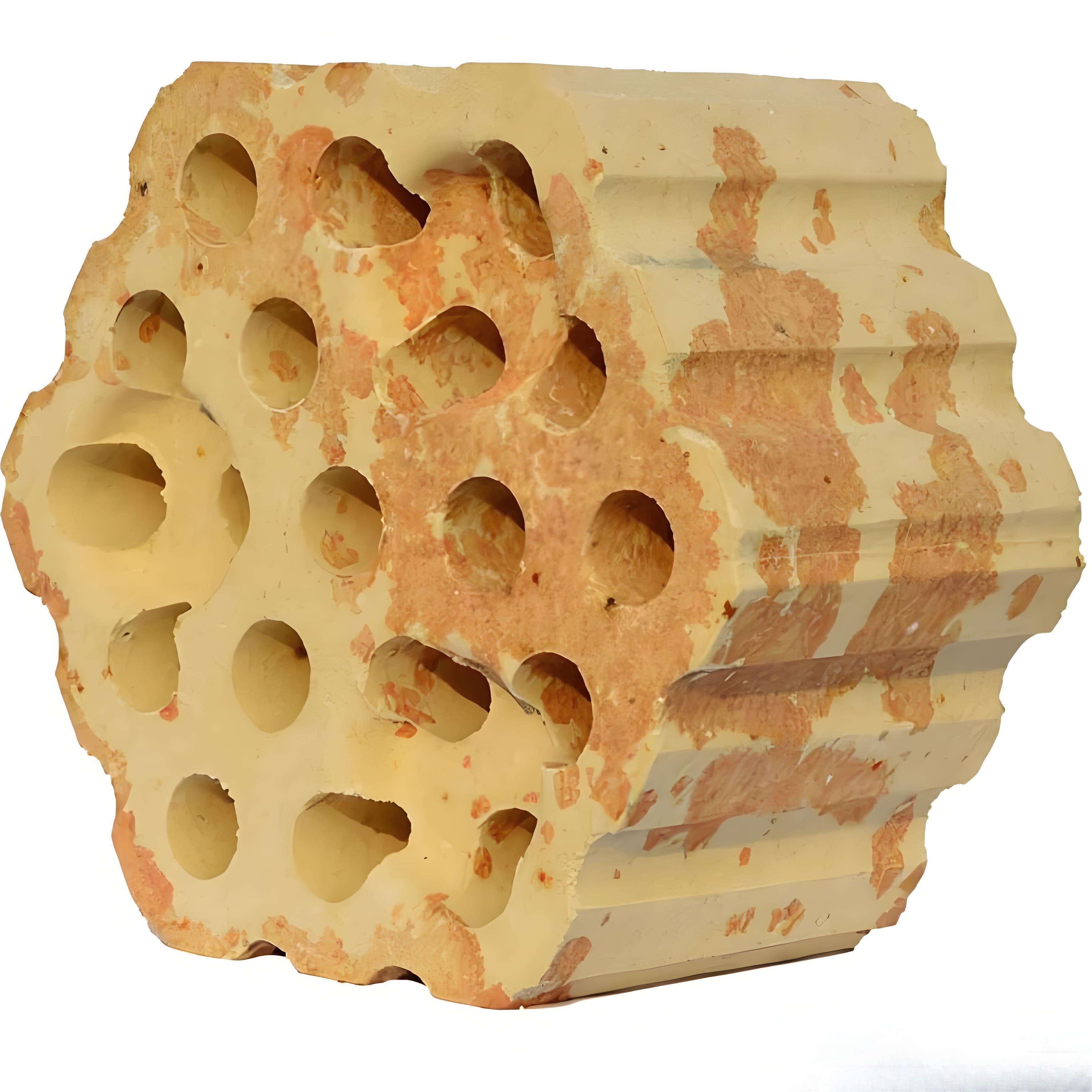

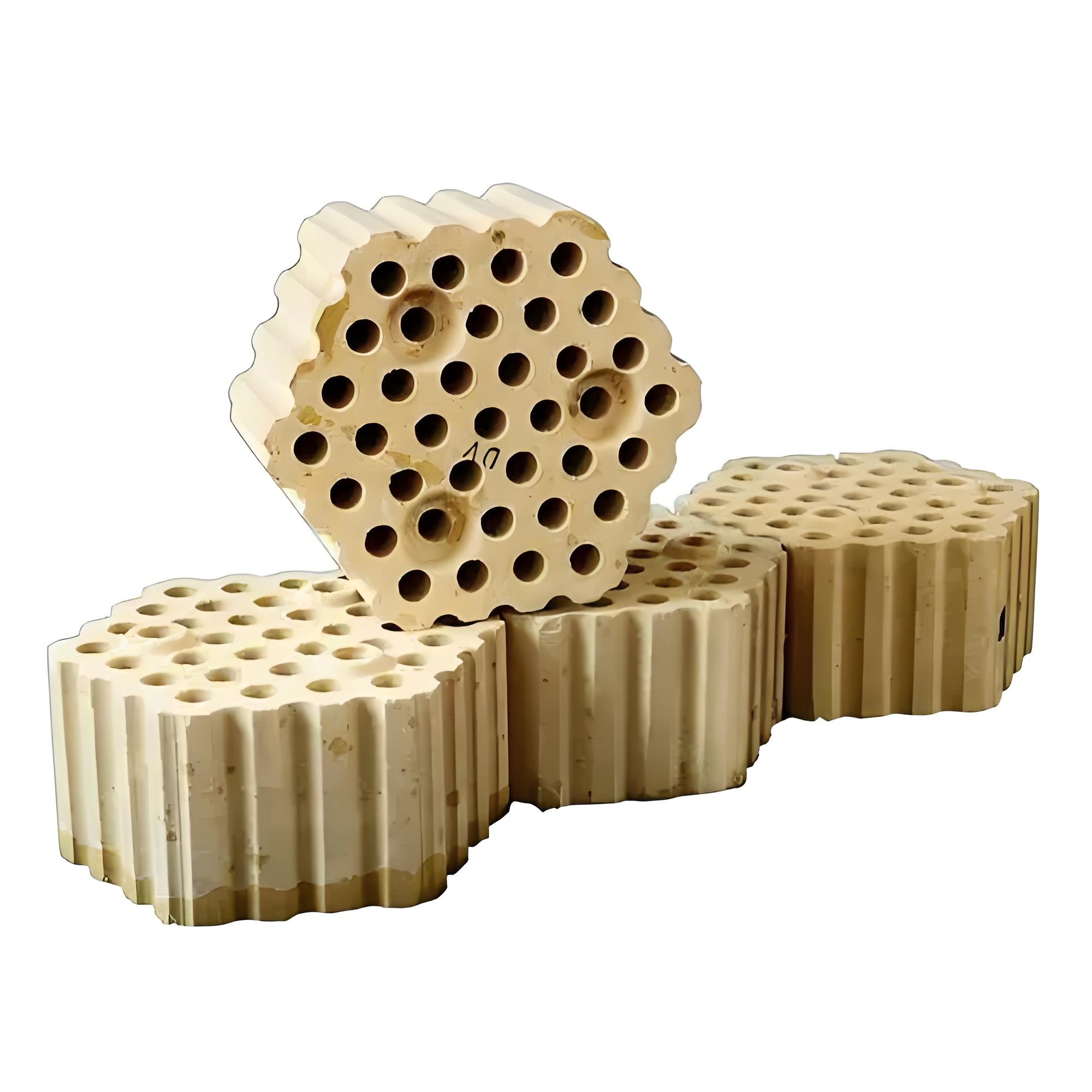

Introducing the Silica Checker Brick from Zhengzhou Rongsheng Refractory Materials Co., Ltd. Specifically engineered for hot blast furnaces, these bricks are a game - changer in the high - temperature industry. Composed of silica, they offer remarkable refractoriness, withstanding temperatures from 1770° to 2000°. Our advanced manufacturing process guarantees precision - crafted bricks that provide superior thermal efficiency and structural integrity. With a bulk density exceeding 2.85 g/cm³, they are incredibly robust. Moreover, we offer customization to meet diverse client needs. Recognized by international certifications such as CE and ISO, our company combines extensive industry experience with a global service network. We've already served over 2000 satisfied customers worldwide, making us a trusted partner for high - temperature solutions.

1. Exceptional refractoriness, able to endure temperatures between 1770° and 2000°. 2. High bulk density over 2.85 g/cm³, ensuring robustness. 3. Precision - crafted through a state - of - the - art manufacturing process. 4. Customizable to meet specific client requirements. 5. Backed by international certifications like CE and ISO, ensuring quality and reliability.

These Silica Checker Bricks are mainly used in hot blast furnace regeneration in the metallurgical industry. They are suitable for clients in countries with a well - developed steel and metallurgical sector. Our products are a great fit for large - scale steel mills, smelting plants, and other high - temperature industrial facilities around the world, offering reliable solutions for thermal management and high - temperature applications.