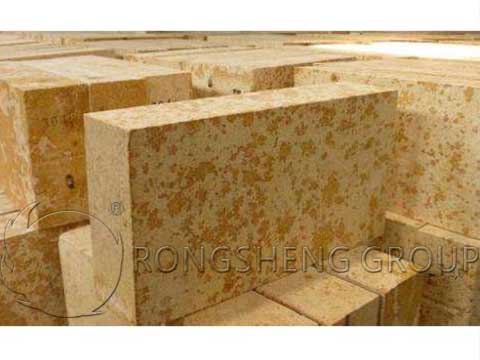

Silica Bricks from Zhengzhou Rongsheng Refractory Materials Co., Ltd. are the ultimate choice for high-temperature industrial applications. Our bricks feature a SiO2 content of over 93%, ensuring excellent thermal stability and refractoriness. Manufactured with an advanced process, we guarantee consistent quality, backed by ISO9001, ISO14001, and various international certifications. With an annual production capacity of 13 million tons, we are well - equipped to meet your large - scale demands. Our R&D team is committed to innovation, providing customized solutions for clients worldwide. Whether you are in the glass, ceramics, or metallurgy industries, our Silica Bricks offer reliability and performance, driving operational efficiency and reducing costs.

1. High SiO2 content exceeding 93% for superior thermal stability. 2. Exceptional refractoriness, suitable for extreme high - temperature environments. 3. High cold crushing strength and low apparent porosity, enhancing durability. 4. Consistent quality ensured by advanced manufacturing processes and international certifications. 5. Customized solutions available to meet specific client requirements.

Our Silica Bricks are widely used in various high - temperature industrial applications. They are ideal for glass furnaces, where they can withstand the harsh conditions of melting glass. In the ceramics industry, they are suitable for ceramic kilns, ensuring stable firing processes. For the metallurgy sector, they are used in blast furnaces and coke ovens. Our products are well - received in international markets, serving clients in industries such as glassmaking, ceramics production, and metal smelting around the world.