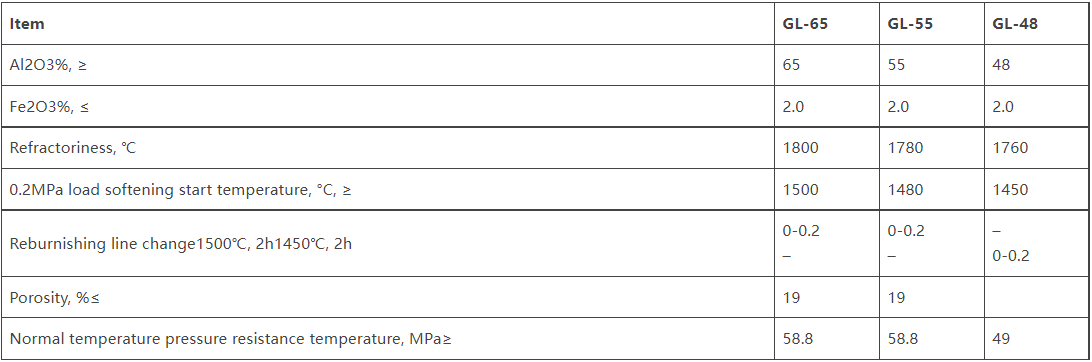

Our High Alumina Mortar, manufactured by Zhengzhou Rongsheng Refractory Materials Co., Ltd, a national high - tech enterprise, is an essential construction material tailored for high - temperature environments. Characterized by a high Alumina (Al2O3) content ranging from 48% to 65%, it provides excellent adherence and thermal insulation. Rigorously tested for high load - softening temperatures and thermal shock resistance, this mortar meets international quality standards and holds numerous certifications. With years of expertise, Zhengzhou Rongsheng is dedicated to delivering top - notch products, ensuring high efficiency in various high - temperature industries globally.

1. High Alumina content (48% - 65% Al2O3) for enhanced heat resistance. 2. Excellent adherence ensures stable bonding of high alumina bricks. 3. Remarkable plasticity and high bond strength. 4. Corrosion resistance, guaranteeing long - term use. 5. Low thermal expansion for dimensional stability in high - temperature changes. 6. Proven high load - softening temperatures and thermal shock resistance.

This High Alumina Mortar is primarily used to bond high alumina bricks in different industrial furnaces, such as hot - blast furnaces, blast furnaces, and regenerative chambers. It suits markets in high - temperature industries including glass and ceramics, electricity, and metallurgy. Various clients from refractory construction contractors to industrial manufacturers involved in high - temperature processes can benefit from our product.