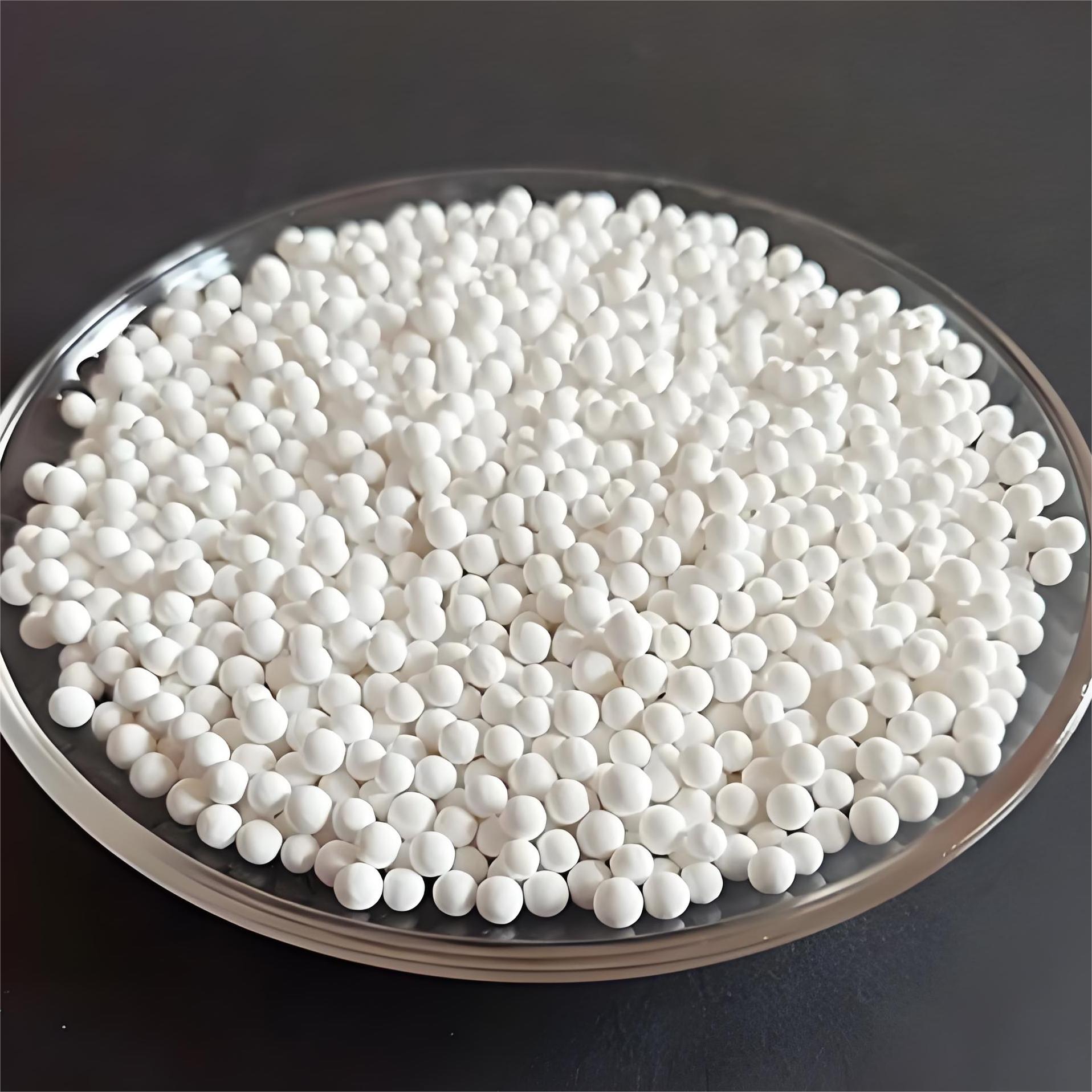

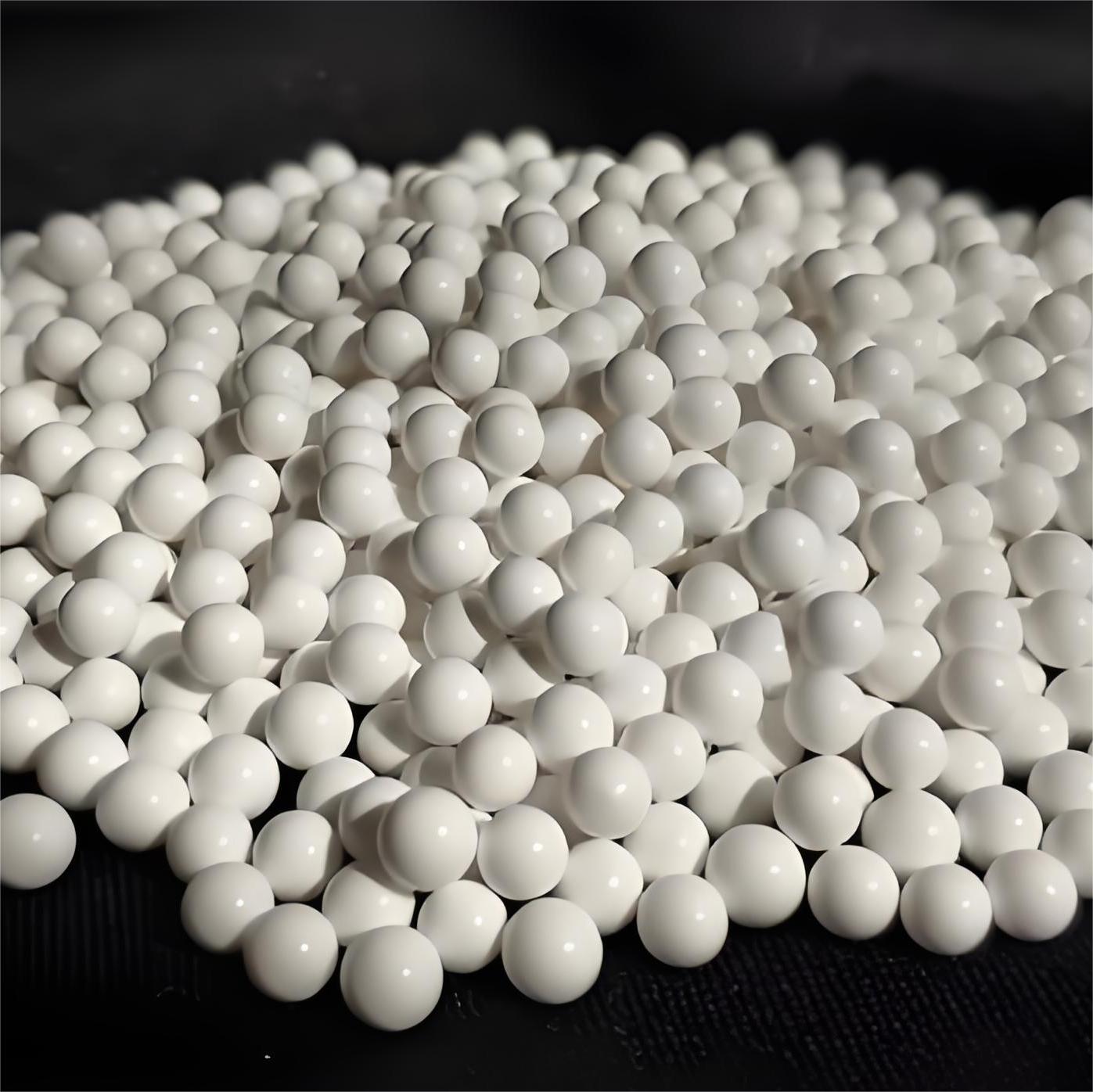

Introducing the Alumina Ceramic Ball from Zhengzhou Rongsheng Refractory Material Co., Ltd., a national high - tech enterprise with rich experience and internationally recognized certifications like CE and ISO. These balls are designed for high - temperature industries, boasting a refractoriness between 1770°C and 2000°C, ensuring excellent performance in industrial furnaces. The content of SiO2, Al2O3, MgO, CaO, CrO, and SiC is customizable, allowing for solutions tailored to specific needs. The innovative design significantly improves heat storage efficiency, which is crucial for energy conservation. Utilizing state - of - the - art automated production lines, we guarantee that each ball meets strict quality standards. Whether you're in power generation, steelmaking, or petrochemicals, our Alumina Hollow Balls are your best choice for maximizing performance and minimizing energy costs.

1. High refractoriness ranging from 1770°C to 2000°C, suitable for extreme high - temperature environments. 2. Customizable content of multiple components to meet diverse industrial requirements. 3. Innovative design enhances heat storage efficiency, contributing to energy conservation. 4. Manufactured by a national high - tech enterprise with CE and ISO certifications, ensuring high - quality and reliable products. 5. Produced on state - of - the - art automated production lines, meeting stringent quality standards.

Our Alumina Hollow Balls are widely applicable in various industries. They are ideal for power generation plants, where they can improve the efficiency of heat - based power generation processes. In the steelmaking industry, they can withstand the high temperatures of steel - making furnaces. Petrochemical plants can also benefit from their heat storage and refractory properties. They are suitable for customers in countries around the world who are looking for high - performance refractory materials for their industrial operations.