In the world of high-temperature industrial applications, the selection of refractory materials is critical. Glass furnace enterprises worldwide are increasingly adopting high-porosity lightweight clay insulating bricks to optimize thermal performance and operational durability. Zhengzhou Rongsheng Refractory Co., Ltd., a trusted name in refractory innovation, stands out by delivering tailored, high-quality solutions that cater precisely to the demanding conditions of glass melting and other high-heat environments.

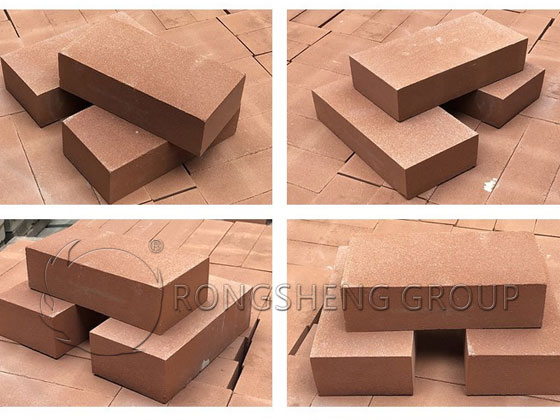

The foundation of a high-performance insulating brick lies in its carefully chosen raw materials and precise manufacturing procedures. High-porosity clay bricks are primarily made from select refractory clays, known for their excellent thermal stability and mechanical integrity. The clay undergoes an advanced shaping and firing process, during which pore formers—such as organic materials or controlled air bubbles—are introduced to achieve a porosity level above 50%.

This careful control results in a brick with low bulk density, typically ranging between 1.2 and 1.5 g/cm³, which significantly reduces heat conduction through the material. Meanwhile, the firing regime ensures the microstructure has sufficient bonding strength, balancing mechanical durability with insulation efficiency.

| Parameter | Typical Range | Significance |

|---|---|---|

| Porosity (%) | 50-60 | Higher porosity lowers heat transfer rates |

| Bulk Density (g/cm³) | 1.2–1.5 | Lightweight improves thermal insulation and handling |

| Cold Crushing Strength (MPa) | >10 | Sufficient to withstand kiln operational stresses |

| Thermal Conductivity (W/m·K at 1000°C) | ≤0.4 | Minimizes heat loss, boosting furnace efficiency |

The superior thermal insulation provided by high-porosity clay insulating bricks contributes directly to improving glass furnace efficiency. By substantially reducing heat loss, energy consumption can be lowered by up to 15-20%, reflected in both operational cost savings and reduced carbon footprint. Furthermore, these bricks protect furnace superstructures against rapid temperature fluctuations and chemical corrosion, extending service life and minimizing maintenance downtime.

Beyond the glass industry, these lightweight insulating bricks support the performance of kilns, furnaces, and other high-temperature equipment used in metallurgy, ceramics, and petrochemical sectors. Their adaptability and resilience make them a go-to choice for demanding thermal insulation requirements.

Zhengzhou Rongsheng Refractory leverages in-depth technical know-how and flexible production lines to offer customized insulating bricks tailored to specific operating temperatures, furnace designs, and client preferences. Key customization parameters include:

These capabilities are backed by comprehensive quality assurance and the company's ISO certifications, reinforcing reliability and consistent product performance.

One flagship glass furnace customer reported a 17% decrease in fuel usage after switching to Rongsheng’s high porosity insulating bricks, directly attributed to improved thermal resistance and lower heat dissipation. Another found the bricks’ superior mechanical strength reduced maintenance frequency by 25%, positively impacting operational uptime.

These verified outcomes demonstrate how technical excellence translates into tangible value—fuel efficiency, cost reduction, and equipment longevity.

We invite technical managers and procurement professionals to engage in a dialogue—what challenges are you facing in refractory insulation? Interested in specific performance data or customization capabilities? Connect with our experts to deepen your understanding or discuss project requirements. Your insights help us innovate better solutions together.