For over two decades, Zhengzhou RongSheng Refractory Materials Co., Ltd. has been at the forefront of delivering advanced refractory solutions worldwide. With more than 20 years of specialized expertise, Rongsheng offers High Alumina Refractory Bricks engineered to withstand the most extreme thermal environments. These bricks are designed not only to meet but exceed the stringent demands across global high-temperature industries like steelmaking, glass production, and cement manufacturing.

At the heart of Rongsheng’s product excellence lies a sophisticated production process combining automated and intelligent manufacturing technologies. These cutting-edge systems ensure consistent quality control and optimized output.

Rongsheng's high alumina bricks contain alumina content ranging from 48% up to over 90%, significantly higher than typical fireclay bricks, which usually have an alumina content of 30-40%. This elevated alumina percentage dramatically enhances the bricks’:

Compared to conventional bricks, Rongsheng’s high alumina bricks offer up to 30% longer service life under comparable operating conditions, translating into significant cost savings and less downtime.

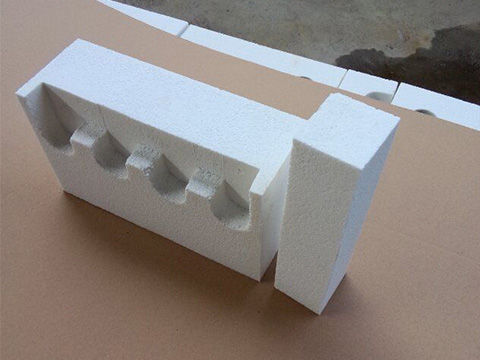

High Alumina Bricks" style="max-width:100%; height:auto; border-radius:8px; box-shadow: 0 4px 8px rgba(0,0,0,0.1);">

High Alumina Bricks" style="max-width:100%; height:auto; border-radius:8px; box-shadow: 0 4px 8px rgba(0,0,0,0.1);">

Rongsheng high alumina refractory bricks have found critical use in industries requiring materials capable of sustaining extreme heat, mechanical stress, and chemical attack:

| Industry | Typical Application | Key Benefits |

|---|---|---|

| Steelmaking | Blast furnace lining, converter linings | High thermal shock resistance, enhanced durability under fluctuating temperatures |

| Glass Industry | Furnace tanks, regenerators | Excellent corrosion resistance to molten glass and chemicals |

| Cement Production | Rotary kiln linings | Stable mechanical strength and resistance to alkali attack |

Trust and quality assurance are paramount when selecting refractory materials. Rongsheng’s high alumina bricks meet rigorous international standards, including ISO 9001 for quality management and ISO 14001 for environmental responsibility. Additionally, these products comply with CE marking, confirming conformity to European safety and environmental requirements.

These certifications underpin Rongsheng’s commitment to sustainable manufacturing and product performance, providing customers worldwide with confidence and peace of mind.

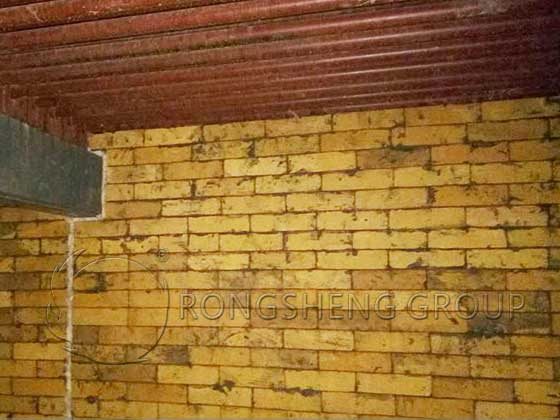

High Alumina Bricks Lining" style="max-width:100%; height:auto; border-radius:8px; box-shadow: 0 4px 8px rgba(0,0,0,0.1);">

High Alumina Bricks Lining" style="max-width:100%; height:auto; border-radius:8px; box-shadow: 0 4px 8px rgba(0,0,0,0.1);">

In summary, Rongsheng high alumina refractory bricks represent a synthesis of advanced manufacturing, superior material properties, and proven field performance. Their ability to withstand high temperatures, corrosive environments, and mechanical stresses makes them an indispensable solution for steel, glass, cement, and many other high-temperature sectors.

As a trusted global supplier, Zhengzhou Rongsheng Refractory Materials Co., Ltd. delivers not only top-quality products but also comprehensive refractory solutions tailored to enhance operational efficiency and stability. For industries looking to optimize thermal management and reduce maintenance downtime, Rongsheng’s high alumina bricks are a reliable partner.