In the world of high-temperature industrial production, every minute counts. Unexpected equipment failure and prolonged downtime can severely impact operational efficiency and financial outcomes. Production stoppages linked to refractory lining damage are not just inconvenient—they can cost industrial plants thousands of dollars per hour. It is in this context that the significance of superior-quality refractory bricks becomes undeniable. Reliable, durable, and thermally resilient refractory materials are pivotal to maintaining continuous operations and reducing costly shutdowns.

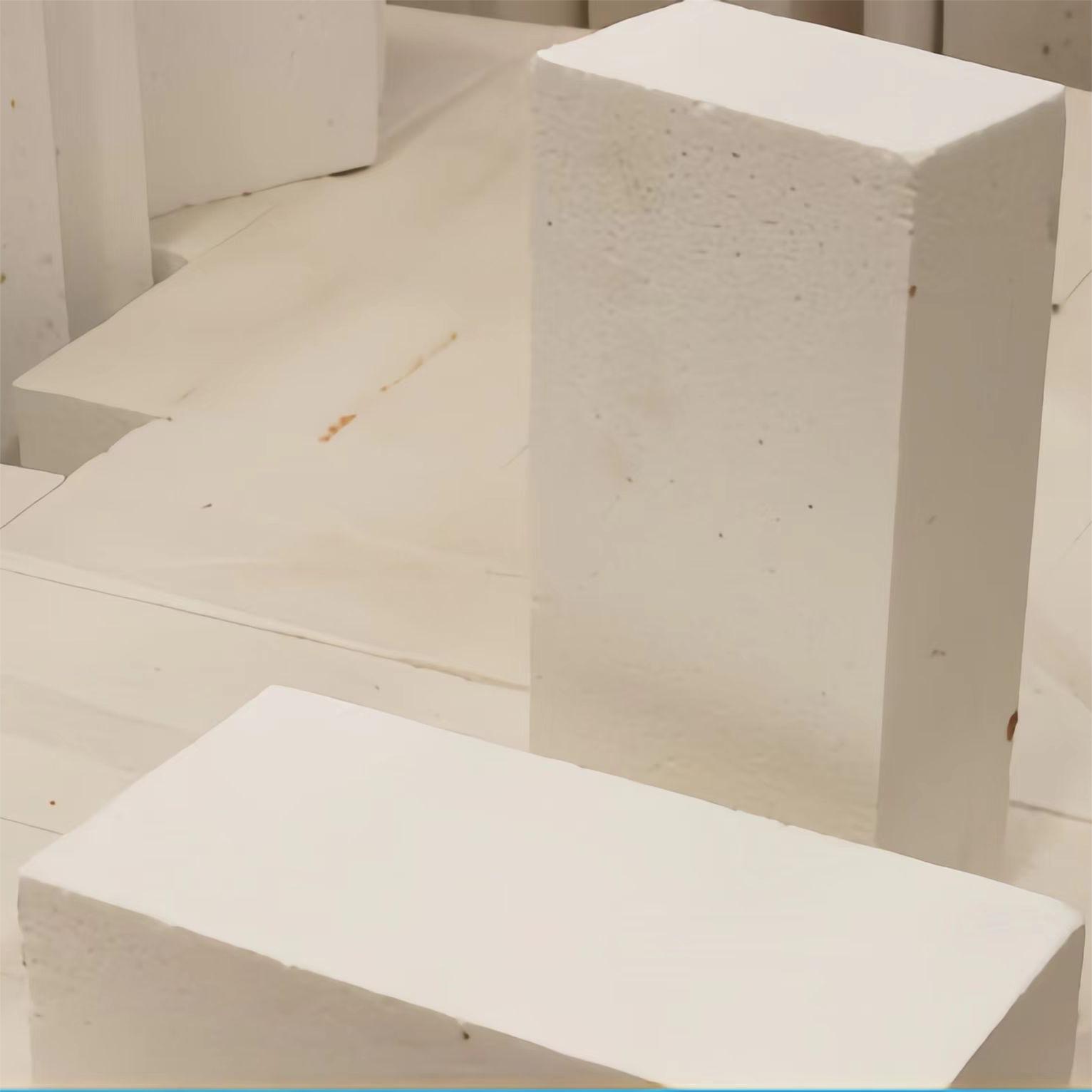

Zhengzhou RongSheng Refractory Materials Co., Ltd., with over 13 years of dedicated industry expertise and advanced R&D capabilities, has developed the corundum brick—a product designed precisely to meet the challenges faced by heavy industries operating at extreme temperatures. This brick combines the best qualities of premium bauxite and zirconia composite materials to produce a refractory brick capable of enduring temperatures from 1770°C all the way up to 2000°C.

The high alumina content provides excellent mechanical strength, while the zirconia component enhances thermal shock resistance, ensuring longevity and minimal wear. These bricks demonstrate a compressive strength exceeding 80 MPa and boast an exceptional thermal conductivity as low as 2.0 W/m·K, which contributes to superior thermal insulation and energy savings.

At the core of the product's reliability is Zhengzhou Rongsheng’s innovative automated production line, which ensures consistent quality and dimensional accuracy for every batch. Automated monitoring minimizes human errors, and the process adheres strictly to ISO9001 quality management standards as well as CE certification. These credentials testify to the brick’s superior manufacturing standards and its suitability for global markets.

Consider a steel plant in Southeast Asia, which switched to the sintered zirconia corundum bricks three years ago. Before the switch, the plant suffered average downtime of 48 hours annually due to refractory failure, costing approximately $500,000 per event. After the transition, refractory wear has decreased by over 40%, and downtime related to lining replacement has been reduced to under 24 hours yearly, effectively cutting related production losses by more than 50%.

This performance owes much to the brick’s excellent thermal insulation, which stabilizes furnace temperatures and reduces thermal cycling stress. Such features enhance overall equipment lifespan and reduce frequent maintenance intervals, directly translating to minimized production interruptions and cost savings.

Beyond product excellence, Zhengzhou Rongsheng has established a robust service network reaching over 30 countries. This ensures both timely delivery and expert technical support, accommodating customized specifications and rapid solutions tailored to diverse industrial environments. Clients consistently commend the company’s attentive service, which reinforces trust and reinforces long-term partnerships worldwide.

corundum brick For buyers seeking to enhance production stability and longevity, this product represents a smart investment in reliability and quality.