Have you ever faced premature equipment failure or costly energy waste due to suboptimal refractory materials in your high-temperature operations? For industries like power generation, steelmaking, and petrochemicals, the resilience and performance of refractory components directly impact operational efficiency and maintenance costs.

Fireclay mullite refractory balls are engineered to withstand severe thermal environments, exhibiting excellent thermal stability up to 1770°C to 2000°C. The high-alumina content within these materials endows them with superior resistance to thermal shock—vital for applications subjected to rapid temperature fluctuations.

This combination of properties assures that your equipment, such as regenerative heating furnaces, maintains integrity during intense cycling, drastically reducing refractory wear and breakdown incidents.

| Property | Fireclay Mullite Balls | Traditional Refractory Materials |

|---|---|---|

| Thermal Stability | Up to 2000°C | Up to 1600°C |

| Thermal Shock Resistance | Excellent (high Al₂O₃ content) | Moderate |

| Mechanical Strength | High | Variable |

| Porosity | Customizable | Fixed |

The dense mullite crystalline structure resists crack formation and propagation during thermal cycling, granting long service life where many standard materials falter.

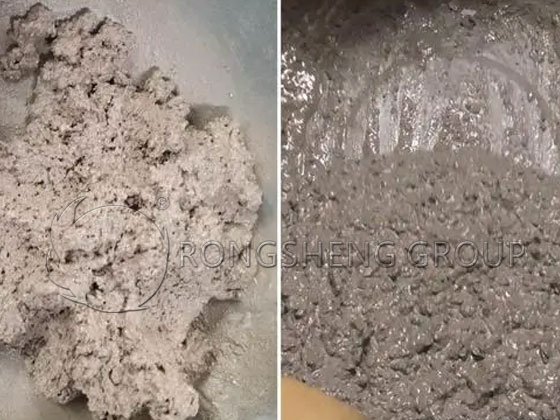

We understand that a one-size-fits-all approach falls short in demanding industrial contexts. That’s why we offer bespoke designs optimized by critical parameters such as size, density, and porosity—factors decisively influencing heat transfer performance and mechanical resilience.

Whether your application requires a refractory ball with enhanced insulation characteristics or improved abrasion resistance, customization ensures the exact fit to your operational needs.

"Our regenerative heater’s operational efficiency rose by over 8% after switching to customized mullite refractory balls, and maintenance intervals extended by 20%. The technical team’s support was instrumental in this success." – Senior Engineer, Steel Manufacturing Plant

Over 2000 satisfied clients globally have validated the long-term cost savings and enhanced equipment uptime made possible by our tailored refractory solutions.

Consider the trade-off between product quality and operational expense: investing in these refractory balls means fewer unplanned shutdowns, lower energy consumption due to optimized heat retention, and reduced material replacement frequency.

Are you ready to move beyond generic refractory materials that merely “get the job done”? Choose advanced technology that bolsters your competitive edge.

Choosing Rongsheng means more than purchasing a product — it’s securing a long-term technology partner who prioritizes your operational goals. Our team consults with you every step, from technical specifications and testing to on-site support ensuring precise application.

Remember, customization is not a burden but the key step towards unlocking significant efficiency improvements and maintenance cost reductions.

Don’t let subpar refractory materials limit your equipment’s potential. Reach out today to explore customized high-alumina fireclay mullite refractory balls designed to meet your exact heat resistance, density, and structural demands.