In high-temperature industrial environments, the reliability of refractory materials directly influences operational efficiency, equipment lifespan, and cost management. Zhengzhou Rongsheng Refractory Materials Co., Ltd., a distinguished national high-tech enterprise with over a decade of international market experience, has continuously set new benchmarks in refractory technology. Their mullite bricks stand out as a prime solution for enduring intense thermal cycles and stress without compromising structural integrity. This article delves into the advanced manufacturing, rigorous quality control, and fundamental material science behind why Rongsheng’s mullite bricks consistently demonstrate superior strength under thermal stress.

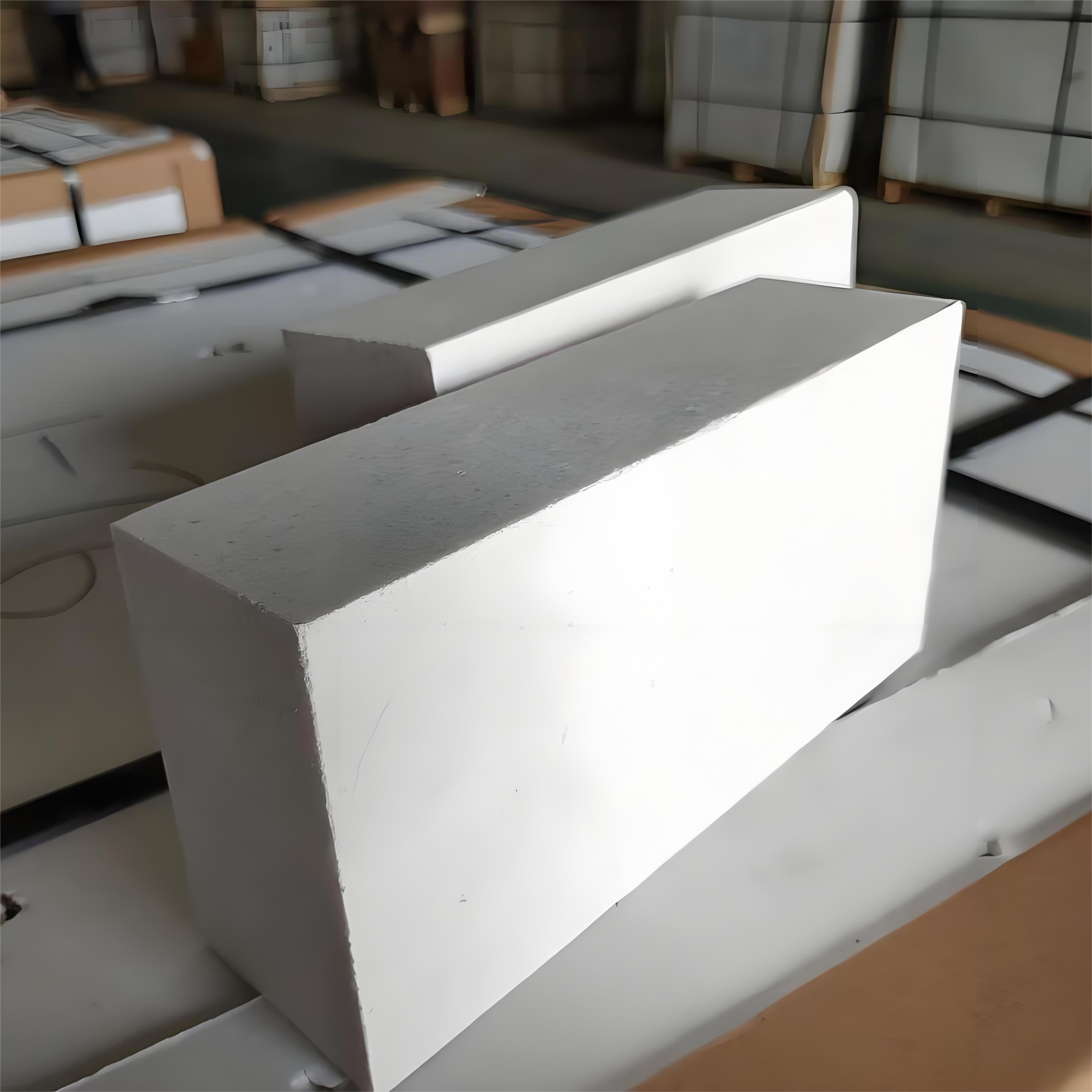

The excellence of Rongsheng’s mullite bricks begins in their state-of-the-art production facilities equipped with automated batch mixing, isostatic pressing, and high-precision firing kilns. These technologies ensure homogeneous microstructures and minimal defects—key factors in heat resistance. Quality control is embedded at every stage, with real-time monitoring of raw materials' chemical composition and mechanical property testing, such as cold crushing strength and hot modulus of rupture, guaranteeing product consistency.

Industry data indicates that Rongsheng’s bricks achieve cold crushing strengths exceeding 160 MPa and maintain more than 70% of their strength at temperatures above 1400°C. Such metrics surpass many traditional refractory bricks, reflecting a robust capacity to withstand spalling and deformation caused by thermal shock and cyclic stresses.

The superior thermal stress resistance and strength of Rongsheng’s mullite bricks arise from multiple technical factors:

| Technical Aspect | Effect on Thermal Stress Strength |

|---|---|

| High Purity Mullite Crystals | Inherently low thermal expansion and excellent creep resistance reduce cracking and deformation during rapid temperature changes. |

| Optimal Porosity Control (~12%) | Balances thermal insulation with mechanical strength, enabling the brick to absorb thermal stresses without catastrophic failure. |

| Isostatic Pressing Manufacturing | Ensures uniform density and minimizes internal flaws, which are common initiation points for thermal cracks. |

| Specialized Firing Schedules | Promote stable microstructure formation that sustains mechanical strength at temperatures exceeding 1600°C. |

In industrial trials involving steel ladle linings and glass melting furnaces, Rongsheng’s mullite bricks demonstrated a 25% longer service life compared to competitor products under similar thermal cycling conditions. Customers have reported a reduction in unplanned shutdowns due to refractory failure by 30%, translating into significant cost savings and process stability.

The insulating properties of the bricks also contribute to up to 8% energy savings by reducing furnace heat loss. This efficiency aligns with industry demands for sustainable and cost-effective production technologies, reinforcing Rongsheng’s commitment to innovation.

Recognizing that each industrial environment poses unique challenges, Zhengzhou Rongsheng Refractory Materials offers comprehensive customization services. This includes variations in brick dimensions, physical properties, and specialized formulations optimized for specific thermal and chemical conditions. Their expert technical team partners with clients throughout project evaluation, supply, and post-installation support to ensure optimal refractory performance.

Zhengzhou Rongsheng’s mullite bricks are the outstanding choice for extreme high-temperature environments; their unique technological advantages bring tangible benefits to your high-temperature equipment. Coupled with their tailored service offerings, they stand as a trusted partner for refractory solutions worldwide.

Have questions or need customized recommendations for your high-temperature refractory applications? Leave your comments below or Contact Rongsheng’s experts directly to discuss how their mullite bricks can enhance your operations. Don’t miss the opportunity to improve equipment lifespan and reduce costs with proven technology.