Industries such as glass manufacturing, ceramics processing, power generation, and metallurgy operate under extreme high-temperature conditions often exceeding 1500°C. Maintaining structural integrity and thermal stability in these harsh environments is a complex challenge. Materials used in furnace linings and refractory applications must exhibit not only strong adhesion and mechanical strength but also excellent thermal insulation and resistance to thermal shock. Failure to meet these demands can lead to critical equipment downtime, safety hazards, and increased operational costs.

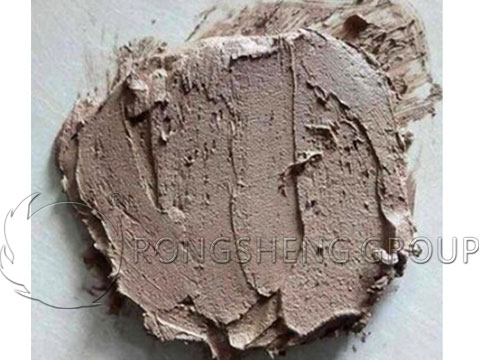

The high-alumina refractory mortar produced by Zhengzhou RongSheng Refractory Material Co., Ltd. is engineered with an optimal alumina (Al₂O₃) content ranging between 48% and 65%, primarily sourced from high-purity bauxite. This carefully calibrated alumina concentration directly influences both the mortar's bond strength and its remarkable thermal insulation properties.

High alumina content enhances the refractory's ability to maintain crystalline stability at elevated temperatures, reducing phase transformations that can weaken the mortar matrix. Moreover, the microstructure, refined through specialized formulation processes, ensures a dense yet thermally resistant composite that minimizes heat conduction and mechanical deterioration over time.

Refractory Mortar" style="max-width: 100%; border-radius: 6px; box-shadow: 0 4px 8px rgba(34, 139, 34, 0.2);">

Refractory Mortar" style="max-width: 100%; border-radius: 6px; box-shadow: 0 4px 8px rgba(34, 139, 34, 0.2);">

Figure 1: Microstructural modification techniques used to enhance bonding and thermal properties.

Extensive field applications demonstrate the mortar’s effectiveness in various sectors:

Refractory Mortar in Application" style="max-width: 100%; border-radius: 6px; box-shadow: 0 4px 8px rgba(210,105,30,0.2);">

Refractory Mortar in Application" style="max-width: 100%; border-radius: 6px; box-shadow: 0 4px 8px rgba(210,105,30,0.2);">

Figure 2: Installation of high-alumina refractory mortar in an industrial glass furnace.

When benchmarked against conventional refractory mortars, Zhengzhou Rongsheng’s product exhibits superior phase stability and adhesion properties. Unlike mortars with lower alumina content, it withstands higher temperatures without significant sintering or cracking. This translates into longer service life, less frequent repairs, and ultimately a better return on investment for industrial operators.

Its formulation also confers excellent compatibility with different refractory bricks and shapes, enhancing installation flexibility. These advantages collectively support higher operational efficiency and production continuity.

Zhengzhou Rongsheng Refractory Material Co., Ltd. is recognized as a national-level high-tech enterprise, underscoring its robust R&D capabilities and commitment to quality. The high-alumina refractory mortar holds multiple international certifications such as ISO 9001 for quality management and ISO 14001 for environmental management systems. These certifications validate the mortar's compliance with stringent global standards, assuring customers of consistent performance reliability and sustainability.

In summary, Zhengzhou Rongsheng’s high-alumina refractory mortar combines optimized alumina content and advanced formulation to deliver stable performance under extreme temperatures. This product is tailored to meet the rigorous demands of high-temperature industries by enhancing thermal insulation, mechanical strength, and longevity. By leveraging this mortar, enterprises can significantly improve production efficiency, reduce downtime, and enhance safety, thereby generating greater operational value.