Technical Analysis: Customizable High-Temperature Refractory Anchor Bricks Customization Service Process

2025-06-29

Technical knowledge

Zhengzhou Rongsheng Refractory Materials Co., Ltd. specializes in high-quality customizable high-temperature clay anchor bricks with exceptional refractory performance ranging from 1770°C to 2000°C, ideal for tunnel kilns and other extreme heat environments. Equipped with advanced production lines and multiple international certifications, Rongsheng offers tailored solutions to meet diverse industrial needs. Trusted by over 2,000 global clients across power generation, steel manufacturing, and petrochemical sectors, this article details the technical service process for customization, highlighting product excellence and broad industrial applications. By exploring concrete data and industry case studies, readers will gain insight into the value these durable, customizable materials provide in demanding high-temperature settings. For those seeking premium, customizable refractory solutions, Rongsheng’s high-temperature clay anchor bricks stand out as the preferred choice—contact us to explore collaboration opportunities.

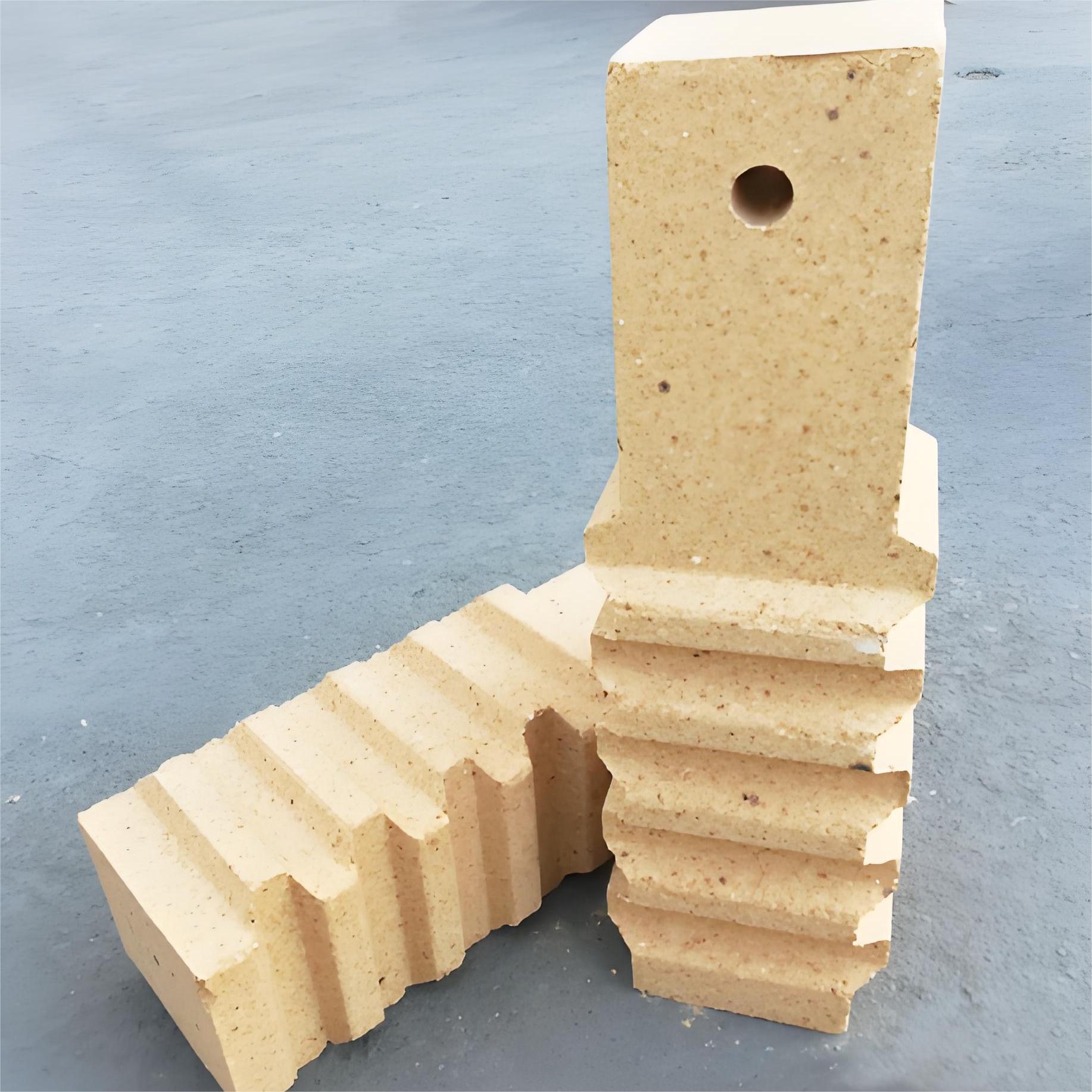

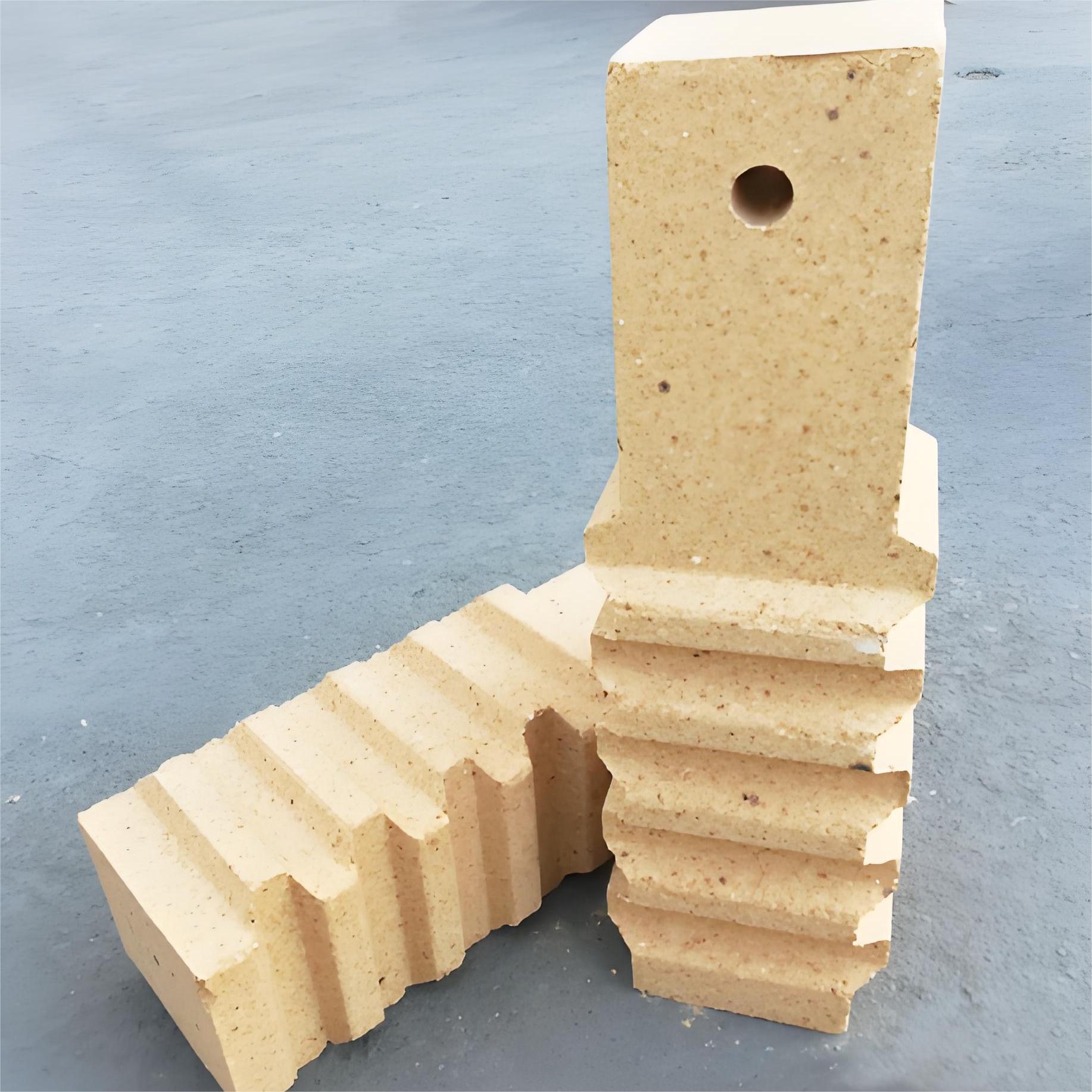

Advanced Customizable High-Temperature Clay Anchor Bricks for Industrial Excellence

In demanding industrial environments such as tunnel kilns, steel manufacturing, petroleum refining, and power generation, the integrity and reliability of refractory materials are critical for operational safety and efficiency. These sectors face extreme thermal challenges, with temperatures often exceeding 1770°C, necessitating durable, heat-resistant solutions. In response, Zhengzhou RongSheng Refractory Co., Ltd. offers premium high-temperature customizable clay anchor bricks engineered to meet diverse industrial needs with precision and proven performance.

Superior Material Composition and Quality Assurance

At the core of Rongsheng's anchor bricks is carefully selected high-quality refined clay, enabling a stable refractory range from 1770°C up to 2000°C. The manufacturing process employs state-of-the-art production lines integrating computerized controls for optimal mixing, molding, and firing, ensuring uniform density and superior mechanical strength. This thorough craftsmanship is validated through multiple international certifications, including ISO 9001 quality management and ASTM refractory standards, instilling confidence in global customers regarding product reliability and longevity.

The physical properties of these anchor bricks include:

| Property |

Specification |

| Refractoriness (°C) |

1770 – 2000 |

| Cold Crushing Strength (MPa) |

≥ 45 |

| Apparent Porosity (%) |

20 – 25 |

Tailored Customization: From Concept to Delivery

Understanding the unique thermal and mechanical requirements of each application, Rongsheng provides a seamless customization service, ensuring clients receive anchor bricks precisely formulated and dimensioned for their operations. The custom service follows a detailed technical flow:

- Requirement Analysis: Technical specialists consult with clients to understand specific temperature ranges, mechanical stresses, installation conditions, and environmental factors.

- Material Formulation: Based on the gathered data, engineers design refractory mixtures optimized for the application, balancing density, thermal shock resistance, and insulation.

- Prototype Sample Production: Customized samples are manufactured and subjected to rigorous laboratory testing to validate performance.

- Client Evaluation and Feedback: Samples are shipped for client trials, with detailed performance feedback collected to refine the product.

- Final Production and Quality Control: Upon approval, full-scale manufacturing is conducted under strict quality controls, ensuring consistency batch after batch.

- Logistics and After-Sales Support: Coordinated delivery schedules, technical support, and maintenance advisory services are provided to optimize installation and lifecycle.

Proven Performance Across Industries

Rongsheng's anchor bricks have been successfully deployed in over 2000 global facilities, illustrating their adaptability and reliability in varied sectors:

- Electric Power Plants: Customized bricks withstand cyclic thermal loads in boiler linings, improving longevity and reducing downtime by 15%.

- Steel Industry: Their superior anchoring performance secures refractory linings in high-velocity tunnel furnaces, enhancing structural integrity under mechanical stress.

- Petrochemical Sector: Resistant to corrosive gases, customized bricks maintain insulation efficiency in catalytic cracking units, supporting continuous operations.

Unlocking Value Through Quality and Customization

The integration of superior material selection, scientific customization, and diligent quality management elevates Rongsheng’s clay anchor bricks as a trusted solution to the complexities posed by high-temperature industrial processes. Clients benefit from enhanced operational safety, extended service life, and tailored performance that reduces both maintenance costs and production interruptions.

If you are seeking high-quality, customizable High-Temperature Refractory Materials that deliver proven durability and precision fit for demanding industrial environments, Zhengzhou Rongsheng Refractory Co., Ltd.’s clay anchor bricks represent your ideal choice. Discover how tailored anchor brick solutions can transform your thermal management system—Contact Rongsheng today for expert consultation and partnership.