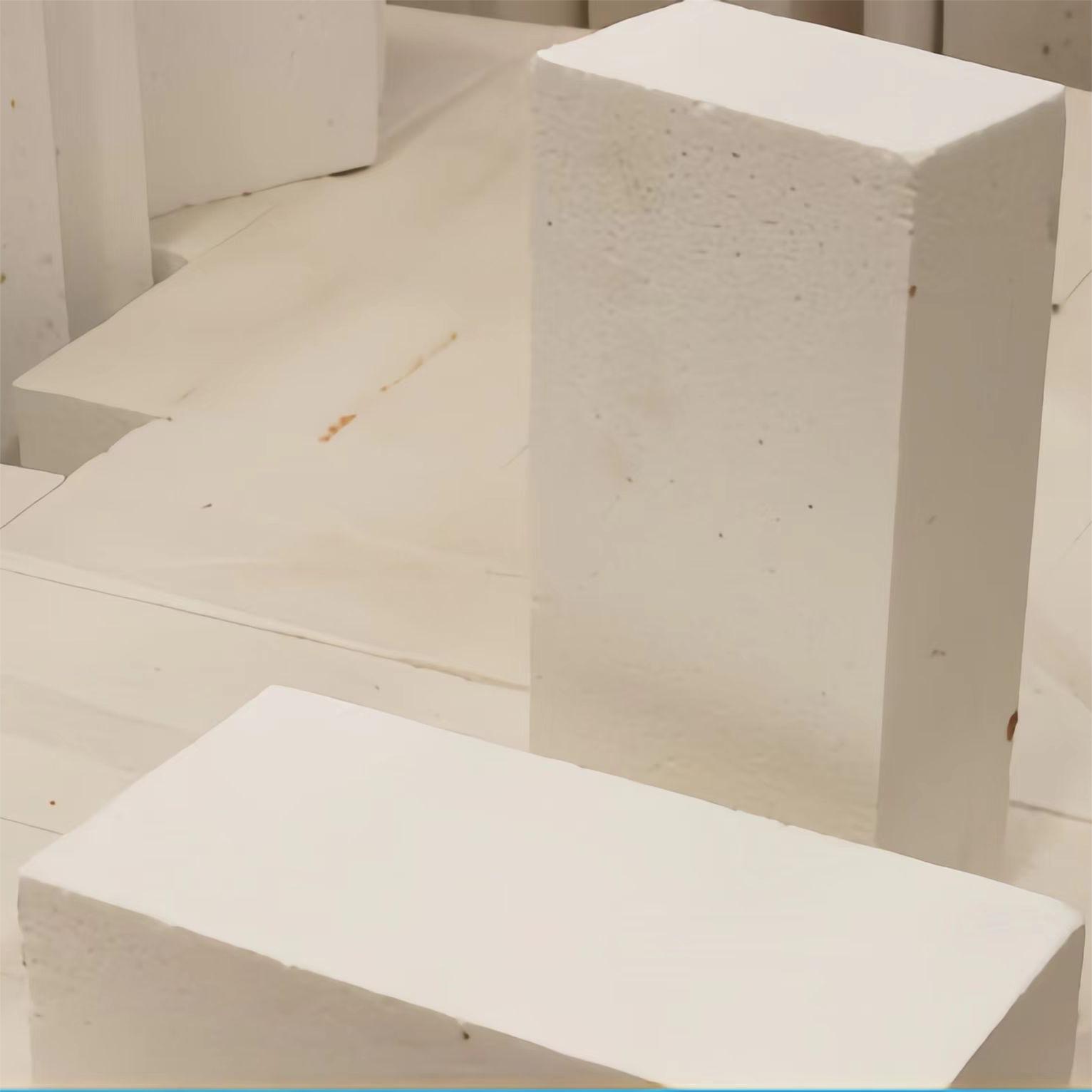

The fused cast aluminum silicate zirconia brick RH-9510 represents a pinnacle in refractory materials designed for demanding high-temperature industrial applications. Manufactured by the renowned Zhengzhou Rongsheng Refractories Co., Ltd., this product combines cutting-edge automated production processes with strict adherence to multiple international certification standards, ensuring consistent quality and reliability.

The RH-9510 zirconia brick stands out for its outstanding properties critical to high-temperature processes. With a remarkable thermal shock resistance, it maintains structural integrity under rapid temperature changes, preventing cracking or spalling. This brick's high durability ensures a long service life even in environments exceeding 1700°C (3092°F), making it ideal for industries such as metallurgy, glass production, and chemical processing.

Specifically, data indicates that the RH-9510 exhibits less than 0.2% linear shrinkage after 24 hours at 1600°C, and a cold crushing strength exceeding 55 MPa post heat-treatment. These metrics confirm its capability to withstand mechanical load and thermal cycling, critical factors for continuous industrial operations.

In practical applications, RH-9510 bricks have been successfully deployed across various sectors:

These diverse applications underline the versatility and reliability of the fused cast zirconia bricks, affirming their status as a preferred refractory choice in critical industrial environments.

A recent collaboration between Zhengzhou Rongsheng Refractories and a leading global glass manufacturer illustrates the value of custom-designed fused cast zirconia bricks. The client required bricks with specific dimensional tolerances and enhanced thermal cycling endurance to upgrade their furnace lining. Rongsheng’s engineering team proposed a tailored specification based on RH-9510 technology.

Leveraging automated production lines and comprehensive quality control aligned with ISO 9001 and ASTM standards, the customized bricks demonstrated a 30% improvement in lifespan relative to previous refractory materials used by the client. This optimization significantly lowered maintenance frequency, reducing furnace downtime by approximately 15 days per year, thereby enhancing overall operational efficiency.

Furthermore, the customized service included on-site technical support, ensuring seamless integration and immediate troubleshooting assistance, solidifying a trusted partnership between manufacturer and end-user.

The advantage of utilizing customized fused cast zirconia bricks like RH-9510 lies in their ability to meet precise operational requirements, optimize furnace performance, and reduce lifecycle costs. Zhengzhou Rongsheng refractories combines advanced material science expertise, flexible customization capabilities, and rigorous quality standards to deliver solutions that add measurable value to industrial clients worldwide.

Whether you face unique furnace design challenges or seek to improve refractory longevity and performance, partnering with an experienced manufacturer like Rongsheng ensures access to products and services tailored to your needs.

Contact Zhengzhou Rongsheng Refractories today to discover how our advanced fused cast aluminum silicate RH-9510 zirconia bricks and expert custom services can enhance your facility’s efficiency and durability. Our technical team is ready to provide tailored recommendations and detailed quotations to fit your application perfectly.