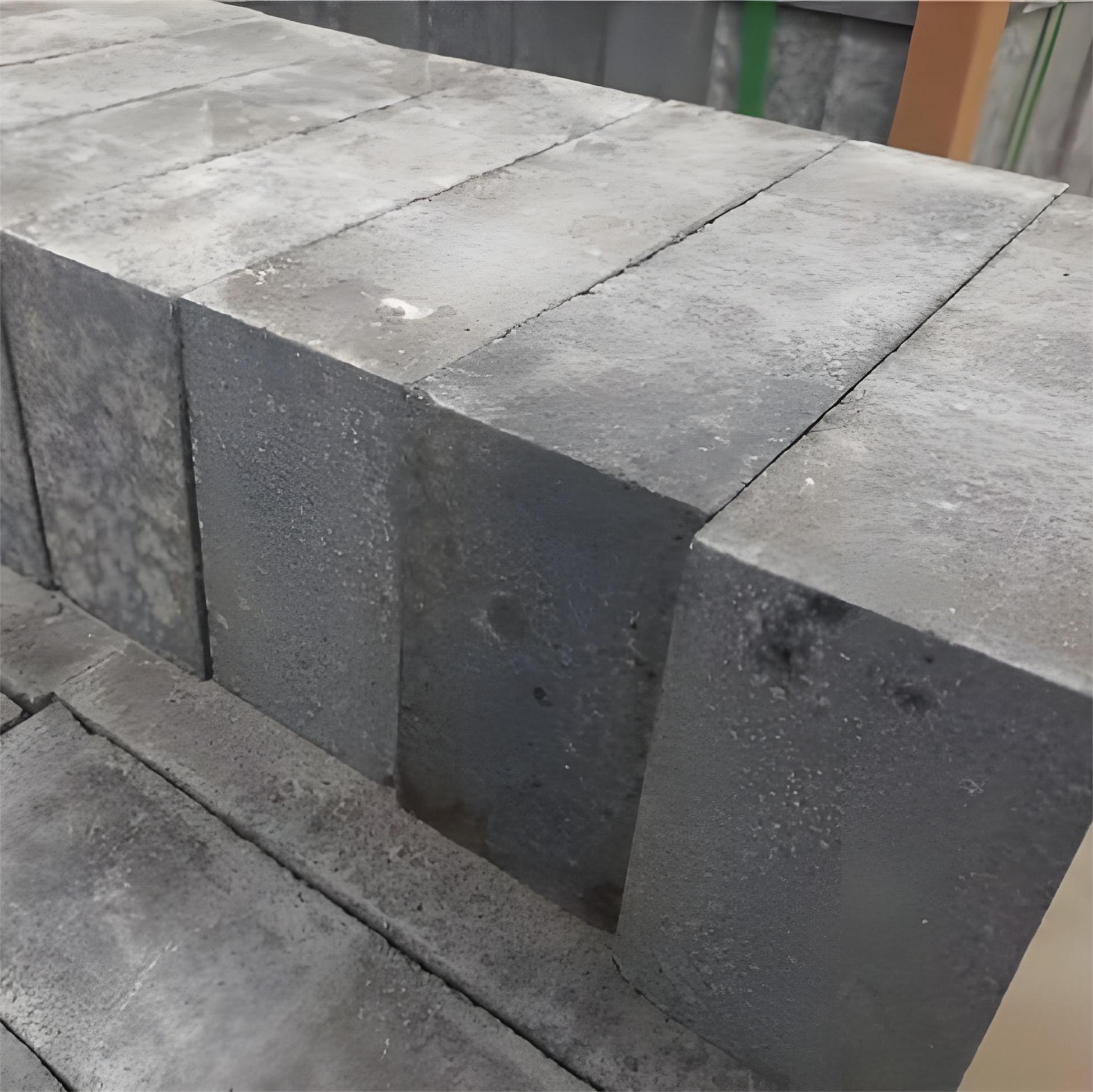

In high-temperature industrial settings, challenges such as extreme heat resistance, chemical corrosion, and thermal shock frequently compromise operational stability and product quality. Selecting the right refractory lining is thus a pivotal factor for manufacturers striving to optimize furnace longevity and enhance product output. Silicon carbide refractory bricks, known for their remarkable durability and thermal efficiency, have emerged as a superior solution in this arena.

Zhengzhou RongSheng Refractory Co., Ltd. offers a premium quality Silicon Carbide Burner Bricks series expertly engineered from top-grade silicon carbide raw materials. These bricks reliably sustain extreme operating temperatures ranging from 1770°C up to 2000°C, ensuring exceptional resistance against thermal shock, chemical corrosion, and mechanical wear.

Compliant with ISO 9001 quality management systems and CE certifications, these refractory bricks meet stringent international standards, reinforcing customer confidence in their consistent performance and longevity. This compliance guarantees that businesses investing in Rongsheng silicon carbide burner bricks adopt globally recognized best practices of manufacturing excellence.

Understanding that every industrial furnace setup has unique operational challenges, Rongsheng specializes in tailored customization options. From dimension adjustments to enhanced material formulations, the company collaborates closely with clients to deliver refractory bricks precisely suited to specific furnace designs and process requirements.

A medium-sized manufacturing plant specializing in ceramic production recently integrated Rongsheng silicon carbide burner bricks into their industrial furnace lining. Prior to the upgrade, the plant faced frequent furnace maintenance downtime and inconsistent firing temperatures, negatively impacting final product integrity and production throughput.

After installation, key performance indicators revealed remarkable improvements:

| Performance Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Furnace Downtime (Hours/Month) | 30 | 12 |

| Product Defect Rate (%) | 5.6 | 1.2 |

| Energy Consumption (kWh/ton) | 850 | 760 |

| Annual Maintenance Cost (USD) | 120,000 | 60,000 |

The data clearly indicate a 60% reduction in downtime, a 79% decrease in defect rate, and nearly 11% energy savings. Most notably, annual maintenance costs halved, demonstrating substantial cost efficiency and operational reliability improvements enabled by Rongsheng’s silicon carbide burner bricks.

For industrial enterprises seeking to improve furnace efficiency, reduce maintenance frequency, and elevate product quality, Zhengzhou Rongsheng's silicon carbide refractory bricks offer a technically advanced, cost-effective solution worthy of consideration.

Discover how customized silicon carbide burner bricks from Zhengzhou Rongsheng can transform your industrial operations.

Contact our experts for a tailored consultation and detailed product information.