In high-temperature industry sectors, the selection of suitable refractory materials is a critical decision that directly influences furnace longevity, operational efficiency, and safety. The challenges imposed by extreme temperatures, thermal cycling, corrosive slags, and abrasive environments demand refractory products with outstanding performance characteristics. High alumina refractory castables, such as those produced by Zhengzhou Rongsheng Refractory Materials Co., Ltd., offer a robust solution, combining advanced material composition and innovative manufacturing technologies to meet these challenges head-on.

Furnaces operating at temperatures exceeding 1400°C experience significant thermal stress, chemical corrosion, and mechanical wear. Selecting refractory materials must consider:

Backing by a national high-tech enterprise like Zhengzhou Rongsheng not only guarantees rigorous R&D processes but also ensures the castable products are developed with cutting-edge technology and stringent quality control. This results in refractory castables with precise Aluminum Oxide (Al₂O₃) content and superior microstructure control, fulfilling demanding industrial requirements.

| Parameter | Typical Value | Industry Benchmark |

|---|---|---|

| Al₂O₃ Content | 85% - 90% | >80% |

| Refractoriness (°C) | ≥1780 | ≥1750 |

| Apparent Porosity | 8% - 10% | ≤12% |

| Cold Crushing Strength (MPa) | ≥85 | ≥70 |

| Thermal Shock Resistance | >20 cycles | 15-18 cycles |

The outstanding features of high alumina castables from Rongsheng are anchored in their composition and microstructure:

A leading steel producer in Eastern Europe faced frequent maintenance intervals due to refractory lining failure caused by slag corrosion and thermal shock. Upon switching to Rongsheng’s high alumina castable, remarkable improvements were documented:

Traditional firebricks or basic refractory mixes often fall short in thermal shock resistance and corrosion protection, limiting their use in highly aggressive environments. By contrast, Rongsheng’s innovative castables leverage superior raw material selection and particle distribution to achieve:

| Feature | High Alumina Castable | Conventional Firebrick |

|---|---|---|

| Max Operating Temperature | ≥1780°C | ~1600°C |

| Thermal Shock Resistance | >20 Cycles | 10-12 Cycles |

| Installation Flexibility | High — Castable Form | Low — Precast Bricks |

| Resistance to Slag Corrosion | Excellent | Moderate |

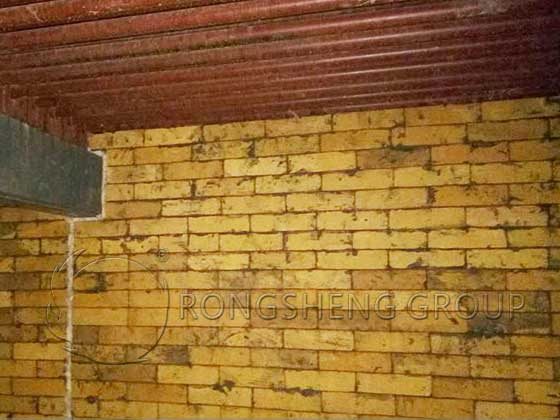

One of the standout benefits of Zhengzhou Rongsheng’s high alumina castables is their flexible installation methods. Whether cast-in-place, shotcrete, or pneumatic ramming, these materials adapt seamlessly to varying high-temperature furnace structures, from steel induction furnaces to cement rotary kilns. This versatility reduces installation time and labor demands while ensuring tight bonding and uniform lining thickness.

In the pursuit of maximizing furnace life and process reliability under extreme thermal stresses, selecting a high-performance refractory is paramount. Zhengzhou Rongsheng’s high alumina castables, with their superior alumina content, low porosity, and resilient mechanical and thermal properties, stand out as an optimal choice for industries demanding robust high temperature material solutions.

From the technical specifications and verified field data, these refractory castables not only provide enhanced thermal shock resistance and corrosion protection but also facilitate faster, more flexible installations – a competitive edge in today’s fast-paced manufacturing landscape.

Would you like to optimize your furnace performance with tailor-made refractory solutions? Contact us now to receive detailed technical guidance and personalized procurement support designed specifically for your high-temperature applications.