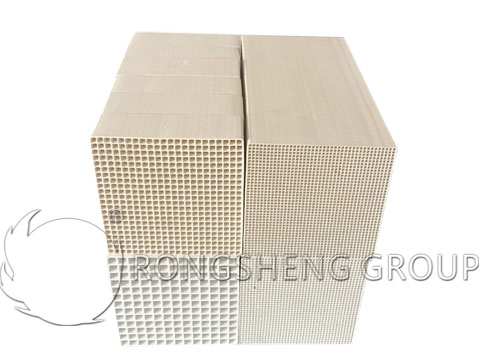

In high-temperature industrial environments, the choice of roller materials significantly influences operational stability, production efficiency, and maintenance costs. Zhengzhou Rongsheng Refractory Materials Co., Ltd. has pioneered the manufacturing of high-purity alumina ceramic rollers specially designed to meet the diverse demands of these sectors. This case study explores how Rongsheng’s custom ceramic rollers, fortified by rigorous CE and ISO certifications, deliver unparalleled performance, helping industries optimize their production processes.

High-temperature industries such as metallurgy, glass production, and advanced ceramics demand rollers that withstand extreme thermal stress, resist wear, and maintain dimensional stability. Ceramic rollers must exhibit:

Rongsheng’s ceramic rollers are engineered with these parameters in mind, tailored to client specifications to ensure seamless integration into existing production lines.

Leveraging high-purity aluminum ore sources, Rongsheng meticulously produces rollers with alumina content exceeding 99.5%—a key contributor to their superior thermal and mechanical properties. The manufacturing process emphasizes:

Comprehensive customization services include diameter adjustments from 50mm to 300mm and length modifications between 200mm to 1500mm, accommodating various equipment models worldwide.

| Parameter | Specification Range | Typical Value |

|---|---|---|

| Bulk Density | 3.60 - 3.85 g/cm³ | 3.75 g/cm³ |

| Max Operating Temp | Up to 1600°C | 1600°C |

| Tensile Strength | ≥ 320 MPa | 350 MPa |

Yongsheng’s commitment to excellence is documented through strict compliance with industry standards. Its ceramic rollers have been certified under:

These certifications provide reassurance to clients worldwide regarding product reliability and consistent performance under demanding operational conditions.

A prominent glass manufacturing plant in Germany integrated Rongsheng’s customized high-purity alumina ceramic rollers as part of their kiln transportation system. The results within the first 12 months included:

The client praised Rongsheng’s responsiveness in customizing roller dimensions and coatings to fit the plant's unique requirements, underscoring the company’s technical expertise and customer-centric approach.

backed by over two decades of refractory materials innovation, Rongsheng blends scientific rigor with customer collaboration to deliver ceramic rollers that:

This combination of quality and flexibility empowers businesses to streamline production workflows confidently, reduce unplanned downtime, and realize sustainable cost efficiencies.