Role and Development Trends of Heat-Resistant Ceramic Fiber Paper in Energy Conservation and Emission Reduction in Industrial Manufacturing

2025-10-15

Industry Research

This article presents an in-depth analysis of the critical role played by Zhengzhou Rongsheng Refractory Co., Ltd.'s 1260°C standard heat-resistant ceramic fiber paper in advancing energy conservation and emission reduction within the industrial manufacturing sector. Highlighting its premium raw materials, broad operating temperature range, and notably low thermal conductivity, the study demonstrates how this product minimizes heat loss, enhances energy efficiency, and reduces operational costs. Addressing real industry demands, the paper also explores the material’s customizable features and comprehensive service benefits that strengthen competitive advantage. Supported by authoritative certifications and customer case studies, this research provides industrial enterprises with scientifically grounded heat-resistant material solutions, promoting efficient energy use and sustainable development.

Energy Efficiency Elevation: The Critical Role of 1260°C Standard Ceramic Fiber Paper in Industrial Manufacturing

In today’s global push toward sustainable industrial practices, reducing energy consumption and minimizing carbon emissions have become paramount objectives. One technology accelerating this transformation is the application of advanced insulation materials. Among them, 1260°C standard ceramic fiber paper stands out for its exceptional thermal resistance and energy-saving capabilities. This article explores how Zhengzhou Rongsheng Refractory Materials Co., Ltd. leverages this material to empower industrial manufacturers in enhancing energy efficiency and achieving meaningful carbon footprint reductions.

Unpacking the Core Performance of 1260°C Ceramic Fiber Paper

Ceramic fiber paper designed for high-temperature insulation exhibits a combination of properties that are critical for industrial heat management:

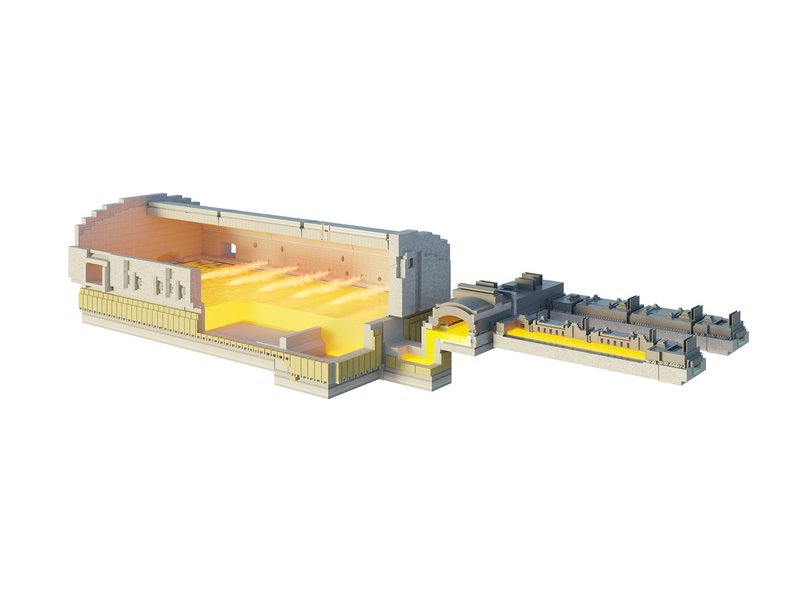

- High Maximum Operating Temperature: Certified for continuous use up to 1260°C, suitable for furnaces, kilns, and heat treatment equipment.

- Ultra-Low Thermal Conductivity: Typical thermal conductivity ranges from 0.12 to 0.15 W/m·K at 1000°C, substantially reducing heat transfer losses compared to traditional refractory materials.

- Superior Chemical Stability: Resistant to corrosion from gases and fumes in industrial environments, ensuring longevity and performance consistency.

- Lightweight and Flexible: Easy to install and adaptable to complex shapes, allowing customized insulation solutions.

Industry Trends Driving Demand for Advanced Thermal Insulation

The industrial sector is currently navigating multiple pressures—including escalating energy costs, regulatory carbon limits, and the urgent call for greener operations. According to the International Energy Agency (IEA), industrial energy consumption accounts for nearly 40% of global final energy use, with nearly 70% of this energy converted into heat in processes.

The demand for materials like 1260°C ceramic fiber paper aligns closely with these trends:

| Trend |

Impact on Thermal Insulation Demand |

| Industrial Decarbonization Initiatives |

Increased adoption of high-efficiency insulation to optimize thermal energy usage and minimize CO₂ emissions. |

| Rising Energy Prices |

Cost-saving through reduced heat loss directly impacts manufacturing margins favorably. |

| Technological Advancement in Materials |

Customizable compositions and form factors meet diverse industrial thermal management needs. |

How 1260°C Ceramic Fiber Paper Drives Energy Efficiency in Practice

Practical implementations demonstrate the material’s significant impact:

- Thermal Loss Reduction: In a steel forging facility, integrating ceramic fiber paper insulation reduced furnace heat loss by over 15%, translating to an approximate 12% decrease in fuel consumption annually.

- Extended Equipment Lifespan: The protective layer mitigates thermal shock and mechanical wear on refractory linings, extending service intervals by 20-30%.

- Custom-fit Solutions: Customized fiber paper density and thickness options precisely meet operational heating profiles, improving insulation efficiency and installation speed.

Certification and Trust: Assurance for Industrial Stakeholders

Zhengzhou Rongsheng is recognized as a national high-tech enterprise and holds multiple ISO certifications, including ISO 9001 for Quality Management and ISO 14001 for Environmental Management Systems. These endorsements guarantee:

- Consistent product quality adhering to stringent industrial standards.

- Commitment to sustainable manufacturing processes.

- Rigorous testing protocols that validate thermal, mechanical, and chemical performance.

Real-World Case Study: Energy Savings in a Ceramic Kiln Operation

A renowned ceramics manufacturer integrated Zhengzhou Rongsheng’s 1260°C ceramic fiber paper as part of their kiln insulation upgrade. After six months:

| Metric |

Before Upgrade |

After Upgrade |

Improvement |

| Energy Consumption (kWh per firing cycle) |

1,800 |

1,530 |

-15% |

| Thermal Efficiency (%) |

72 |

83 |

+11% |

| Kiln Downtime (hours/month) |

20 |

14 |

-30% |

These improvements not only yield immediate cost savings but also contribute significantly to the facility’s sustainability goals.

Customized Solutions and Comprehensive Support

One of the notable advantages offered by Zhengzhou Rongsheng is the ability to tailor ceramic fiber paper products to exact customer requirements in terms of thickness, density, and size — optimizing insulation performance across a variety of industrial applications. Their technical team provides:

- On-site thermal consultation to identify key loss points.

- Material testing and certification assistance.

- Post-installation performance monitoring and service.

Ready to upgrade your industrial energy efficiency with reliable, high-performance 1260°C ceramic fiber paper?

Contact Zhengzhou Rongsheng today to discuss tailored thermal insulation solutions that fit your operational needs and sustainability ambitions.

Feel free to leave your questions or experience insights below — let’s collaborate to foster a greener, more energy-conscious industrial future.