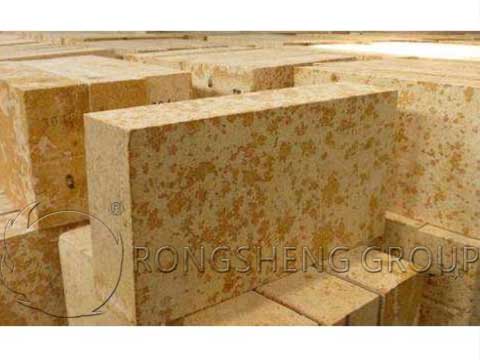

In the demanding realm of industrial high-temperature applications, selecting refractory materials that combine both exceptional heat resistance and adaptability can be quite challenging. Zhengzhou Rongsheng Kiln Refractory Materials Co., Ltd., with over 13 years of specialized experience and a clientele exceeding 2000 satisfied customers worldwide, offers an innovative solution: customizable silicon bricks optimized for hot blast furnaces capable of stable operation from 1770°C to 2000°C.

As a nationally recognized high-tech enterprise, Zhengzhou Rongsheng has built a reputation across 70 countries by consistently delivering durable, high-performance refractory materials. Their commitment to quality is notably reflected in their fully automated production lines and cutting-edge manufacturing technologies, which together ensure product consistency and reliability even under extreme thermal stress.

The hallmark of Rongsheng’s silicon bricks lies in their customizable silicon content, which enables precise tailoring of thermal and mechanical properties suited to diverse industrial scenarios. Operating reliably in the 1770°C to 2000°C temperature range, these bricks boast strong thermal stability and enhanced resistance to thermal shock — critical factors for maintaining structural integrity in high-temperature environments.

| Property | Typical Range | Benefit |

|---|---|---|

| Silicon Content | Customizable (Typically 70~98%) | Optimizes thermal conductivity and mechanical strength |

| Operating Temperature | 1770°C - 2000°C | Maintains structural integrity under extreme thermal loads |

| Thermal Stability | High resistance to thermal shock and chemical erosion | Extends lifespan, reduces downtime |

These silicon bricks are not just limited to hot blast furnaces. Their robust performance under high temperatures makes them ideal for power generation equipment, metallurgical processes, and chemical reactors. Even in challenging environments like glass production and cement manufacturing, their adaptability provides companies with the versatility to meet evolving operational demands.

A leading metallurgical company in Eastern Europe faced recurring issues with refractory material degradation, leading to frequent shutdowns and maintenance costs that accounted for 12% of annual operational expenses. After switching to Rongsheng’s customizable silicon bricks designed for temperatures up to 2000°C, the plant reported a 40% decrease in refractory-related downtime within six months, accompanied by improvements in thermal efficiency that translated into energy savings of approximately 5%. These improvements not only reduced costs but also contributed to the plant’s sustainability goals by cutting emissions associated with energy consumption.

One cannot overlook the impact of Rongsheng’s fully automated production lines, which incorporate real-time monitoring and precision molding techniques. This approach ensures minimal variances between batches, translating to consistent product quality. The advanced manufacturing technology also reduces human error and improves scalability, allowing buyers to secure long-term supply with confidence.

While traditionally applied in heavy industry, the potential of these customizable silicon bricks extends to emerging sectors, including advanced ceramics and environmentally focused industries such as waste incineration plants. Their ability to endure extreme thermal cycles makes them particularly attractive for companies striving to optimize asset longevity and fulfill sustainable development commitments.

So, how do you evaluate the refractory materials you currently use in your high-temperature operations? Are they truly delivering the durability and efficiency needed, or is it time to consider a tailored solution that can actively reduce maintenance cycles and improve thermal performance?