In today's demanding construction and industrial environments, materials used for high-temperature applications must deliver exceptional performance and durability. Whether in steel manufacturing, furnace linings, or other heat-intensive sectors, the structural integrity of refractory materials directly impacts operational safety and efficiency. Procuring refractory materials with proven heat resistance, mechanical strength, and long service life is a critical decision for global buyers aiming to maximize uptime and optimize cost-effectiveness.

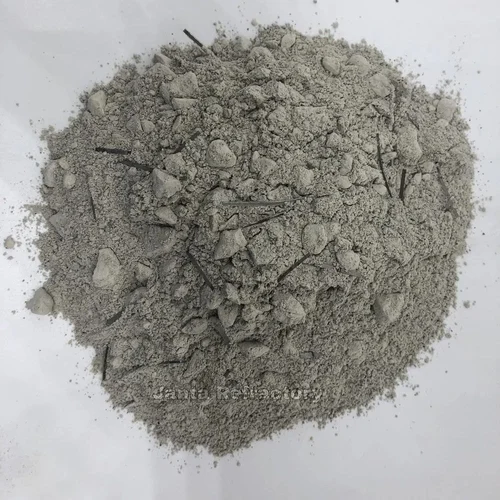

Understanding this industry imperative, Zhengzhou RongSheng Refractory Co., Ltd. offers an advanced steel fiber-enhanced refractory castable, crafted primarily from premium-grade bauxite—the finest available raw material known for its superior refractory properties. This castable material is a carefully engineered blend of high-purity bauxite and multiple functional additives, thoughtfully proportioned to excel under extreme thermal stress.

The inclusion of steel fibers greatly enhances the castable’s mechanical strength and resistance to thermal shock. This innovation effectively prevents the formation and propagation of microcracks during rapid temperature changes, a common failure mode in refractory materials. Independent laboratory tests confirm that the product withstands over 1,400°C repeatedly without structural degradation, outperforming many traditional Refractory Castables by up to 25% in mechanical resilience under thermal cycling.

Compared to standard refractory mixtures, this steel fiber-reinforced product shows a 30% higher hot modulus of rupture (HMOR), an essential indicator for load-bearing capacity in furnaces and ladles. The composite material also delivers superior erosion resistance under high-velocity molten metal flows, extending service life and reducing costly downtime.

Quality assurance is paramount for buyers in this sector. Zhengzhou Rongsheng’s refractory castable proudly holds ISO9001 certification for quality management, ISO14001 for environmental standards, and GB/T28001 occupational health and safety certification. These rigorous certifications affirm the company’s commitment to product excellence, environmental stewardship, and workforce safety.

Over 70 countries have adopted this refractory castable to safeguard their high-temperature applications with confidence. From steel plants in Europe to foundries in Asia and South America’s glass manufacturing hubs, the product’s reputation is built on proven performance and responsive service.

Refractory Castable" style="width: 100%; max-width: 800px; margin: 20px 0; border-radius: 8px;">

Refractory Castable" style="width: 100%; max-width: 800px; margin: 20px 0; border-radius: 8px;">

| Feature | Standard Refractory Castables | Rongsheng Steel Fiber-Reinforced Castable |

|---|---|---|

| Hot Modulus of Rupture (HMOR) | Up to 35 MPa | Up to 45 MPa (≈30% higher) |

| Thermal Shock Resistance Cycles | ~200 cycles | >250 cycles (≥25% improvement) |

| Service Life Expectancy | Up to 12 months | Up to 18 months |

| Certifications | Limited or Regional | ISO9001, ISO14001, GB/T28001 |

Selecting the right refractory material can safeguard your operations, reduce maintenance overheads, and enhance productivity under extreme conditions. Zhengzhou Rongsheng’s steel fiber-reinforced refractory castable stands out as a reliable choice among industry peers, combining premium raw materials, validated testing, and wide global acceptance.

Interested in elevating your high-temperature projects with proven refractory technology?

Contact Zhengzhou Rongsheng now to request detailed product information or receive your complimentary sample for evaluation. Experience firsthand why over 70 countries trust our refractory solutions.

Request Product Info & Samples