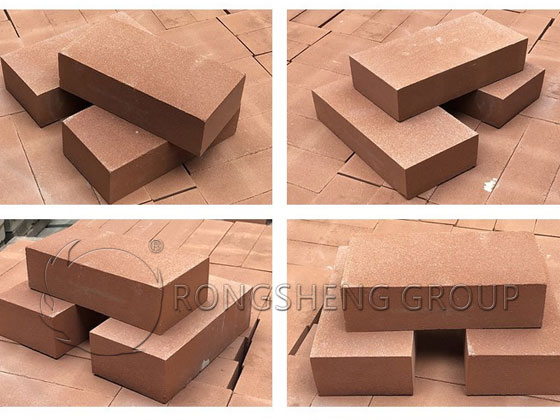

Zhengzhou Rongsheng Refractory Materials Co., Ltd. is dedicated to producing high - quality lightweight refractory clay insulation bricks. These bricks are made from carefully selected raw materials, mainly high - quality clay with an aluminum ore content ranging from 30% to 40%. This specific composition provides a solid foundation for the excellent performance of the bricks.

The manufacturing process of these bricks is advanced. First, the raw materials are finely ground to ensure uniform particle size. Then, they are thoroughly mixed to achieve a homogeneous blend. After that, the mixture undergoes high - pressure molding to form the basic shape of the bricks. Finally, the bricks are fired at high temperatures, typically between 1300°C and 1400°C, which enhances their physical properties.

The physical properties of lightweight refractory clay insulation bricks are remarkable. They have a high porosity, usually around 40% - 50%. This high porosity contributes to their low volume density, which can be as low as 0.8 - 1.2 g/cm³. At the same time, they possess good mechanical strength, with a compressive strength of about 3 - 5 MPa, ensuring their durability in various applications.

When comparing lightweight refractory clay insulation bricks with ordinary insulation bricks, the differences are significant. In terms of thermal insulation performance, the lightweight bricks outperform ordinary ones. The high porosity of lightweight bricks creates a large number of tiny air pockets, which act as excellent thermal insulators. For example, in a thermal boiler application, the heat loss of a system using lightweight refractory clay insulation bricks can be reduced by about 20% - 30% compared to a system using ordinary insulation bricks.

In addition, lightweight refractory clay insulation bricks have better stability at high temperatures. In high - temperature environments such as glass kilns, cement kilns, and electric furnaces, ordinary insulation bricks may experience cracking or deformation, while lightweight bricks can maintain their shape and performance. A customer in the glass industry reported that after replacing ordinary insulation bricks with Zhengzhou Rongsheng's lightweight bricks, the service life of the kiln insulation system was extended by nearly 50%.

Zhengzhou Rongsheng understands that different customers in the high - temperature industries have diverse requirements. Therefore, the company offers customized services. The customization process starts with in - depth communication with customers to understand their specific needs, such as special sizes or performance indicators.

For example, a cement plant needed insulation bricks with a special shape to fit their unique kiln structure. Zhengzhou Rongsheng's R & D team designed a customized solution. By adjusting the molding process and raw material formula, they successfully produced insulation bricks that met the plant's requirements. As a result, the plant's energy consumption was reduced, and production efficiency was improved.

Zhengzhou Rongsheng Refractory Materials Co., Ltd. has a long - standing reputation in the refractory materials industry. With over 20 years of experience, the company has a strong R & D team and advanced production equipment. The company also holds multiple international quality certifications, such as ISO 9001, which ensures the high - quality and reliability of its products.

In conclusion, Zhengzhou Rongsheng's lightweight refractory clay insulation bricks offer superior performance, excellent customization services, and a reliable brand guarantee. Whether you are in the thermal boiler, glass kiln, cement kiln, or electric furnace industry, these bricks can provide you with the best insulation solution.

Are you ready to upgrade your high - temperature insulation system? Click here to learn more about our lightweight refractory clay insulation bricks and customized services!

We would love to hear your thoughts and questions. Please leave a comment below and start a conversation with us!