High-temperature environments pose significant challenges to industrial insulation systems, where maintaining thermal stability and efficiency directly impacts operational costs and safety. Industries such as power generation, ceramics manufacturing, and metallurgy constantly seek materials that offer superior heat resistance, durability, and easy installation. ceramic fiber board address these demands with advanced technology and proven performance.

Manufactured using high-quality aluminum silicate fibers, these ceramic fiber boards deliver outstanding thermal insulation properties. Their low thermal conductivity — measured at approximately 0.12 W/m·K at 800°C — significantly reduces heat loss, enabling clients to achieve up to 25% energy savings compared to conventional insulation materials. This translates into measurable operational cost reductions and enhanced environmental sustainability in high-temperature processes.

Beyond insulation, the boards feature impressive compressive strength, ensuring mechanical stability under pressure and thermal cycling. These mechanical characteristics result in longer service life, lowering maintenance frequency and costs.

| Property | Value | Unit |

|---|---|---|

| Thermal Conductivity @ 800°C | 0.12 | W/m·K |

| Compressive Strength | 3.5 | MPa |

| Maximum Service Temperature | 1260 | °C |

Rongsheng’s ceramic fiber boards comply with stringent international certifications, including ISO 9001 for quality management and ASTM standards specific to thermal insulation materials. Such credentials ensure consistent product reliability critical in high-risk industrial settings. The boards undergo rigorous quality control tests — thermal insulation performance, durability under cyclic heating, and chemical stability — guaranteeing they perform reliably even under the harshest conditions.

These boards are widely utilized in power plants for furnace linings, ceramic kilns, and metallurgical heating processes, where they provide effective insulation that enhances process efficiency and equipment longevity. For example, a leading ceramics manufacturer reported a 20% reduction in energy consumption after retrofitting using Rongsheng’s boards, confirming the product's tangible benefits.

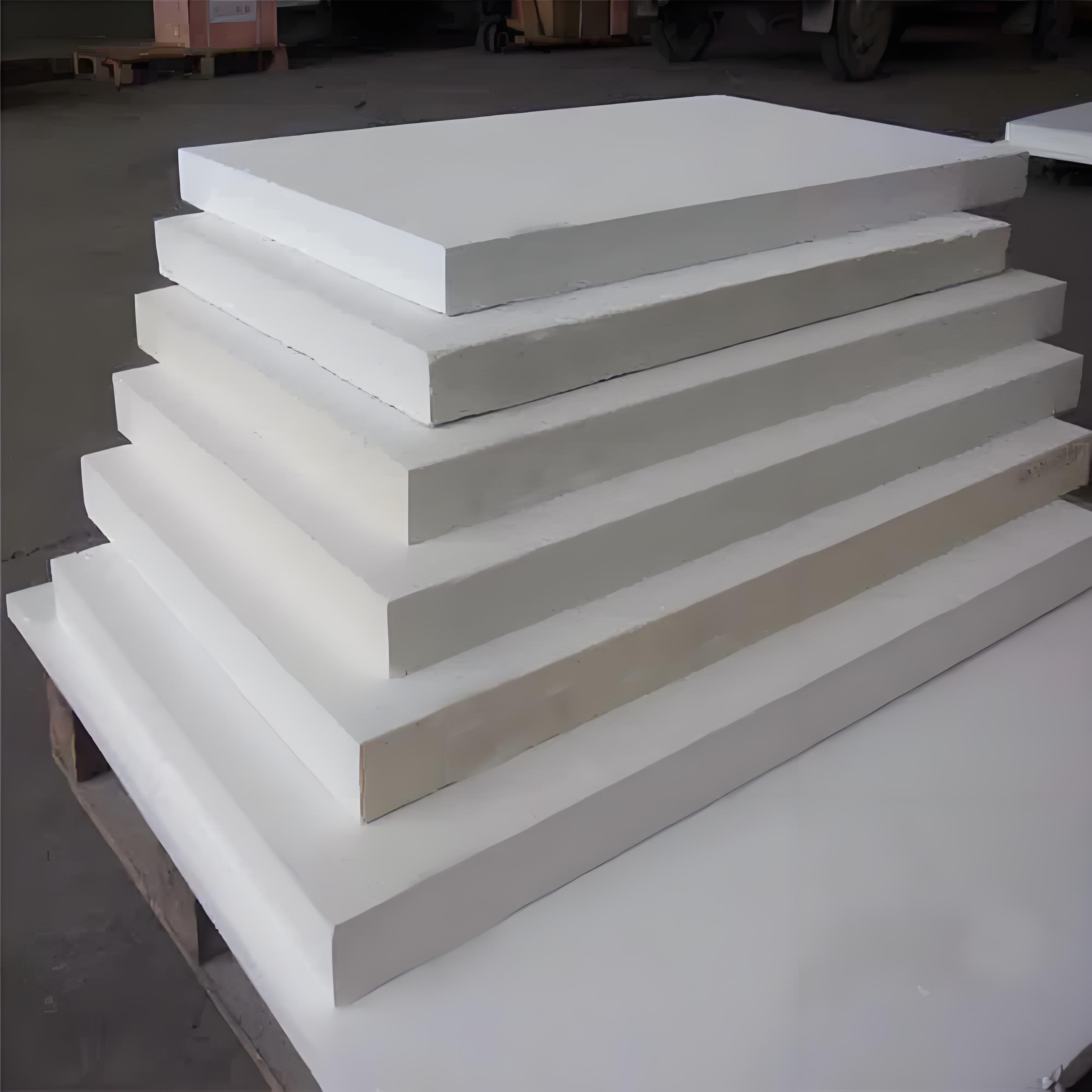

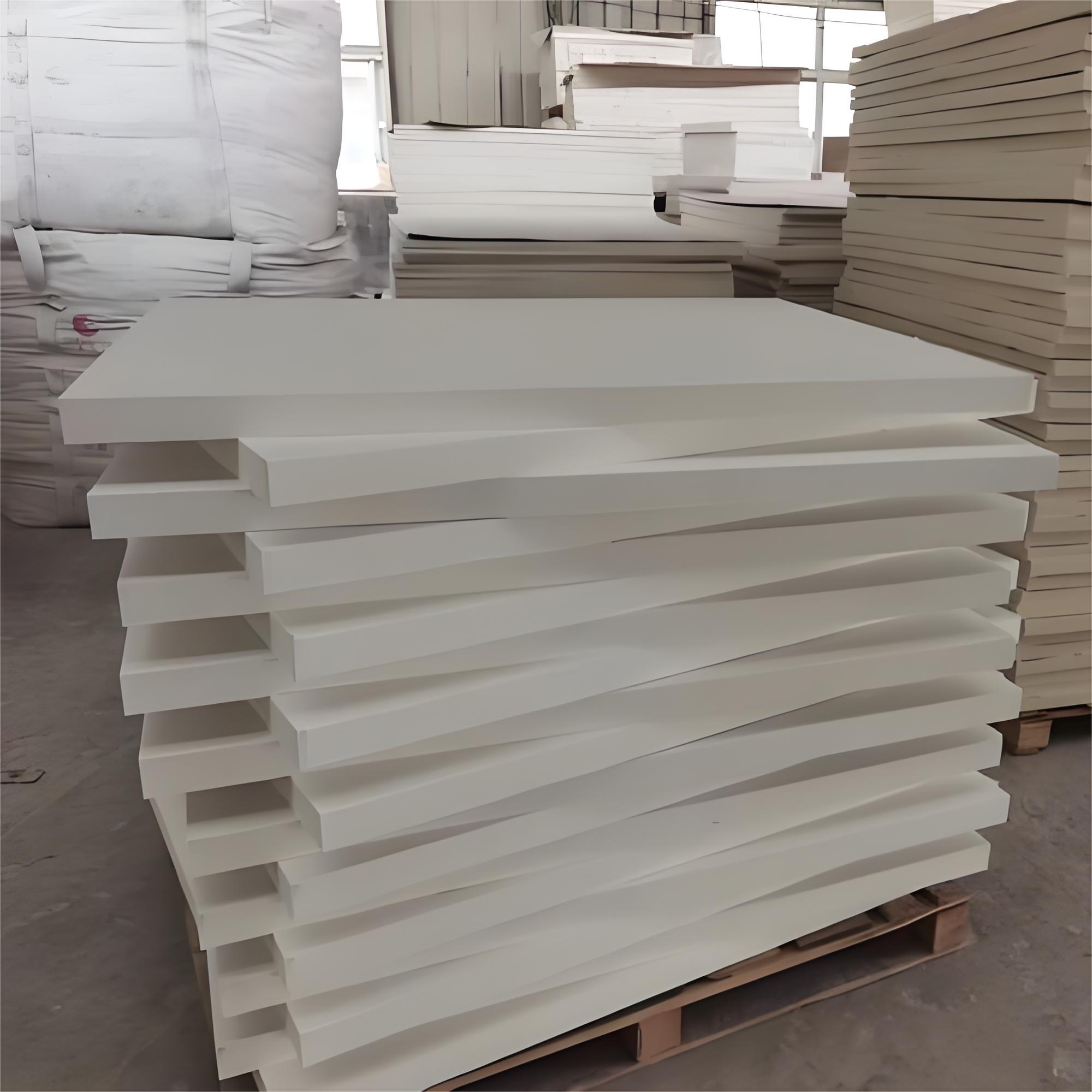

Their lightweight yet sturdy design simplifies on-site handling and installation—allowing technicians to cut and fit the boards according to precise requirements. This flexibility reduces labor time and costs significantly, accelerating project timelines without compromising insulation quality.

Understanding that every industry and project has unique demands, Rongsheng offers customized ceramic fiber board solutions. Customers can specify dimensions, density, and performance parameters to perfectly match their thermal management needs. This bespoke approach ensures maximal efficiency and compatibility with existing systems.

From large-scale power generation facilities to niche high-precision applications, Rongsheng supports global clients with expert technical consultation and dependable supply chain management.