In today’s competitive industrial landscape, optimizing energy efficiency while maintaining operational reliability is paramount. The refractory lining within industrial furnaces plays a pivotal role in thermal management, safety, and longevity of operations. Among innovative solutions, ceramic fiber modules by Zhengzhou RongSheng Refractory Co., Ltd. stand out as a cutting-edge choice for high-temperature insulation. These modules are meticulously engineered to simplify kiln construction and deliver outstanding thermal insulation performance at temperatures ranging from 1050℃ to 1400℃.

This advanced ceramic fiber module offers a low thermal conductivity typically in the range of 0.12 to 0.18 W/m·K at operating temperatures, substantially reducing heat loss compared to traditional refractory bricks. This characteristic directly contributes to elevated energy conservation and reduced fuel consumption — an industrial imperative given rising energy costs and environmental regulations.

Furthermore, its outstanding thermal shock resistance ensures the refractory lining remains structurally intact during rapid temperature fluctuations common in intense industrial processes. Testing reveals these modules endure over 50 cycles of thermal shock without cracking or deformation, significantly extending service life and decreasing maintenance downtime.

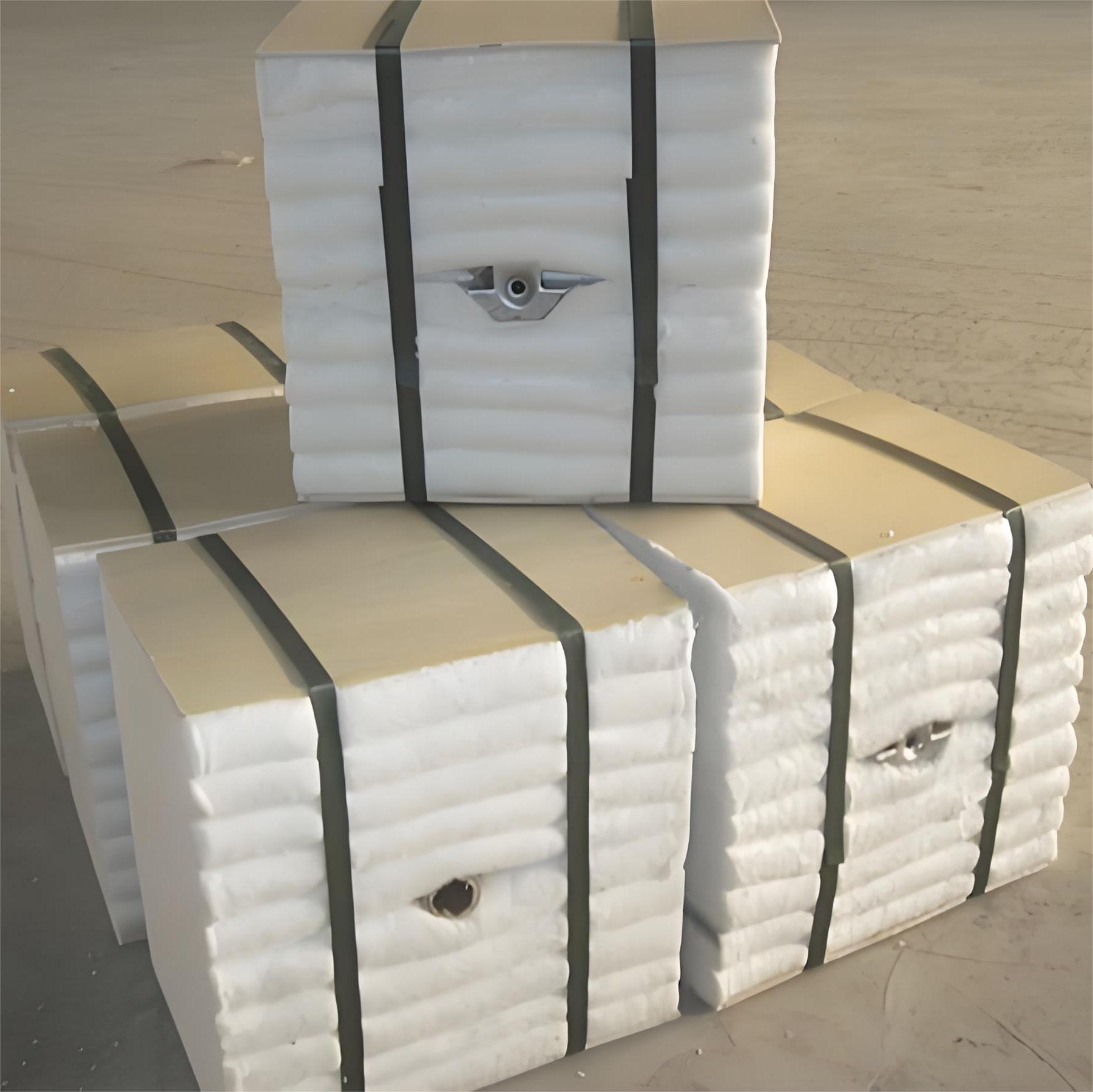

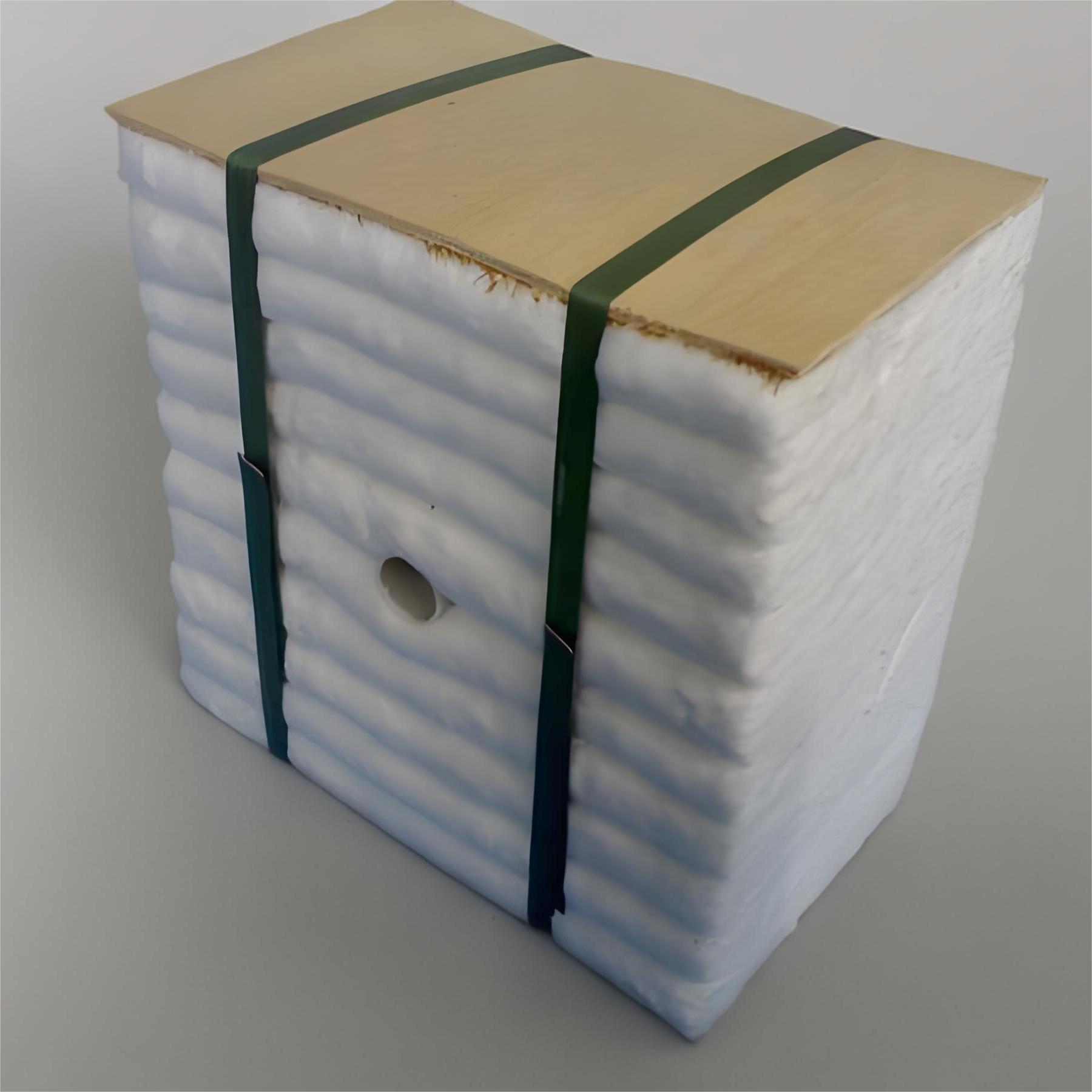

The installation process has been streamlined using anchor bolt fixation, enabling direct and secure attachment to the furnace’s steel plate framework. This convenient installation not only reduces labor time by approximately 30% compared to conventional methods but also minimizes errors and ensures consistent lining integrity across large furnace surfaces.

Leading steel manufacturers have successfully integrated these ceramic fiber modules into their reheating furnaces, achieving up to 15% reduction in fuel consumption annually. Similarly, petrochemical plants utilizing these modules in their catalytic reforming units report enhanced thermal insulation stability and reduced thermal cycling damage.

Additionally, the ceramics industry benefits from these modules in tunnel kiln lining, where elevated temperature endurance and rapid installation accelerate production schedules while maintaining consistent product quality.

Table: Application Benefits Summary

| Industry | Energy Savings (%) | Installation Time Reduced (%) | Average Service Life (years) |

|---|---|---|---|

| Steel | 15 | 30 | 8-10 |

| Petrochemical | 12 | 25 | 7-9 |

| Ceramic | 10 | 20 | 6-8 |

Industrial enterprises often wrestle with refractory material degradation, complex installation logistics, and energy inefficiency during kiln construction and operation. The modular design of Rongsheng’s ceramic fiber panels enables quick replacement of damaged sections without dismantling entire linings, reducing unplanned downtime.

The products’ compatibility with anchor bolt installations significantly curtails installation complexity, lowers labor costs, and fosters safer working conditions. Additionally, its thermal insulation properties help stabilize kiln internal temperatures, ensuring smoother process control.

Compared with conventional dense refractory bricks, ceramic fiber modules showcase advantages in weight reduction — approximately 60% lighter — which alleviates structural load on kiln frameworks. Moreover, their superior thermal insulating capacity translates to up to 20% fewer energy losses during operation.

While traditional castables require lengthy curing times and significant moisture control, ceramic fiber modules significantly shorten construction timelines, eliminating curing phases and permitting faster furnace commissioning.

Zhengzhou Rongsheng’s ceramic fiber modules hold multiple international certifications, such as ISO 9001 for quality management and ASTM standards for refractory performance. These attestations affirm the product’s compliance with stringent industrial quality criteria, underpinning reliable long-term operation.

The deployment of these high-performance refractory modules represents a strategic investment towards industrial sustainability. By effectively minimizing heat loss and extending lining lifespan, enterprises can substantially lower fuel consumption and carbon emissions.

This ceramic fiber module is an excellent choice for industrial companies dedicated to advancing eco-friendly operations and cost efficiency. Its integration supports meeting increasingly rigorous environmental standards, contributing to global efforts in energy conservation.