In the demanding arena of industrial high-temperature applications, material performance and reliability are critical for operational efficiency and cost control. Zhengzhou RongSheng Refractory Co., Ltd., a nationally recognized high-tech enterprise, has strategically positioned itself as a leading manufacturer with its latest innovation: the alumina hollow ball brick. This technologically advanced refractory product boasts an alumina content exceeding 90%, ensuring superior thermal stability and resistance under extreme kiln operating conditions.

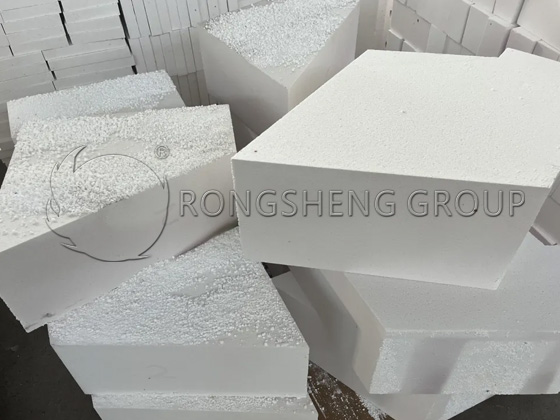

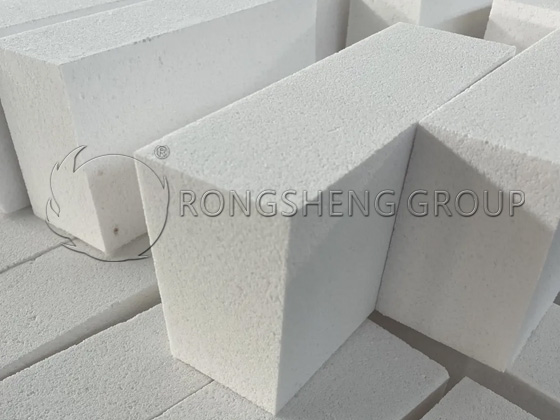

The core advantage of Rongsheng's alumina hollow ball bricks lies in their high-purity alumina raw material. With an alumina content surpassing 90%, predominantly derived from premium-grade bauxite, these bricks demonstrate exceptional mechanical strength and chemical inertness essential for industrial kilns exposed to thermal cycling and corrosive atmospheres. Such a composition renders them highly resistant to thermal shock, slag attack, and abrasion.

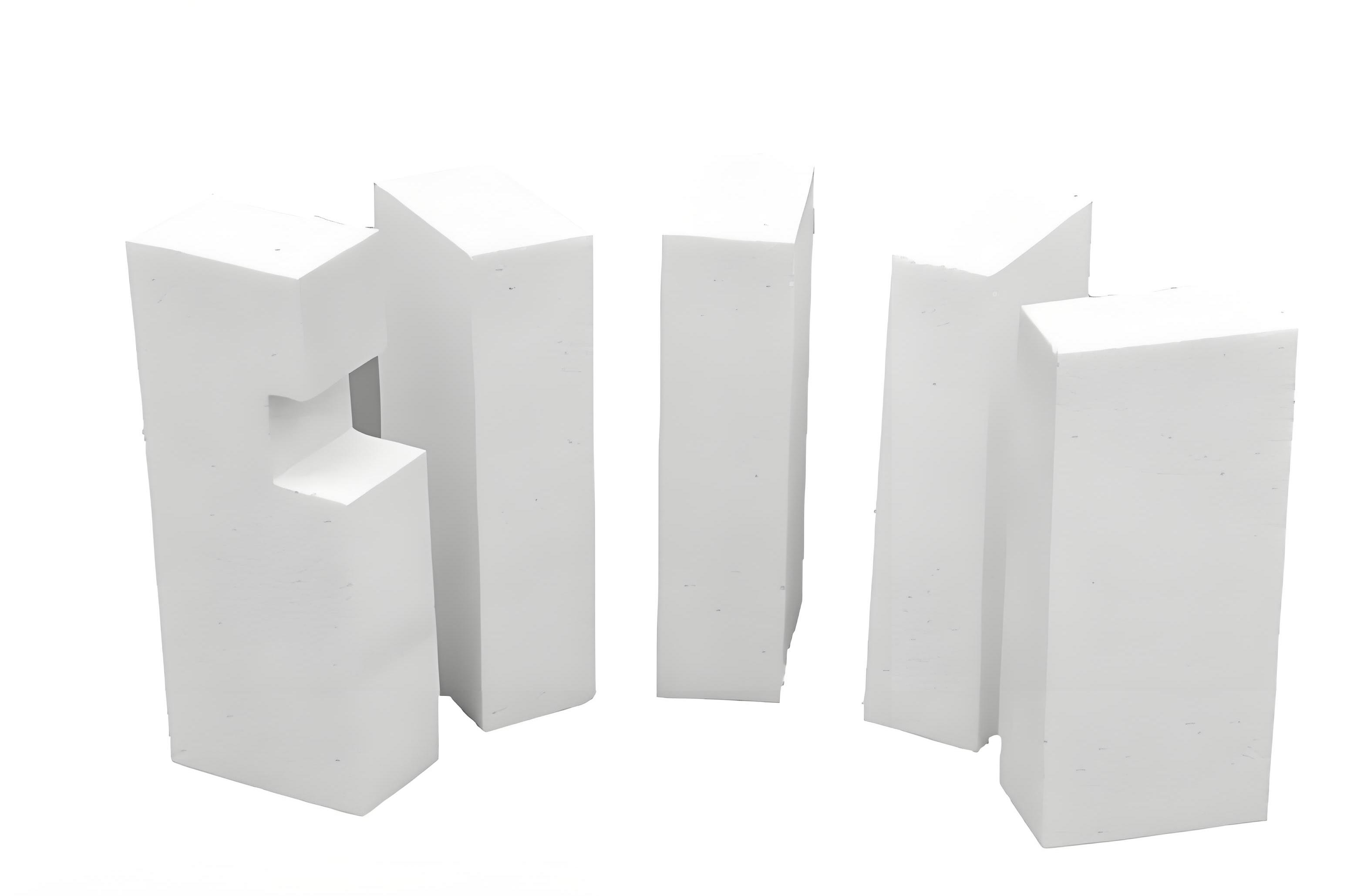

A defining feature of these bricks is their unique hollow spherical microstructure. This design innovation significantly reduces the product’s density without compromising mechanical integrity, resulting in lighter bricks that alleviate structural load on kiln linings. Furthermore, the hollow ball formation imparts improved thermal insulation properties, effectively minimizing conductive heat loss.

From an operational standpoint, the reduced brick weight translates into easier installation and decreased downtime during kiln maintenance. Most importantly, the superior insulation capability leads to significant energy savings, optimizing fuel consumption and lowering overall production costs — key factors for industries driven by cost-efficiency and sustainability goals.

The product’s excellence is further validated by its ISO certification, a hallmark of adherence to stringent international quality and management standards. This certification guarantees consistent product reliability and safety, reassuring global clientele of its compliance with rigorous industrial benchmarks.

Currently, Zhengzhou Rongsheng’s alumina hollow ball bricks have been exported to over 70 countries worldwide, spanning markets in Europe, Asia, the Americas, and Africa. This extensive global footprint underscores the material’s proven performance and the company's capability to meet diverse customer requirements across variable industrial conditions.

Integrating this ISO-certified alumina hollow ball brick into industrial kilns enables enterprises to enhance thermal efficiency and extend service life, thereby reducing replacement frequency and maintenance expenditure. The bricks’ outstanding insulation performance directly contributes to reduced energy consumption, aligning with global trends toward green manufacturing and sustainability.

As a high-tech enterprise committed to innovation, Zhengzhou Rongsheng deploys cutting-edge production technologies and rigorous quality control systems to ensure each batch meets exacting standards. This robust technical foundation empowers clients with a reliable refractory solution that strengthens operational resilience and fosters business growth.

Discover how this alumina hollow ball brick can elevate your kiln’s efficiency and durability.

Contact Zhengzhou Rongsheng Refractory Co., Ltd. today to request detailed technical specifications and a customized supply proposal.

This certified innovation is your industrial high-temperature application’s key to superior energy savings and enhanced competitiveness.