Zhengzhou Rongsheng Refractory Materials Co., Ltd., a national high - tech enterprise with 13 years of industry experience, is making waves in the global market with its customizable industrial kiln ceramic slurries. These slurries are designed to meet the most demanding high - temperature processes, offering a unique combination of performance and environmental compliance.

The industrial kiln ceramic slurries from Zhengzhou Rongsheng come with a wide range of customizable compositions, including SiO2, Al2O3, MgO, CaO, CrO, and SiC. Each component plays a crucial role in meeting different high - temperature process requirements. For example, SiO2 can enhance the thermal shock resistance of the ceramic slurry, while Al2O3 significantly improves its refractoriness.

According to industry research, over 70% of high - temperature industrial processes can benefit from the customized composition of these ceramic slurries. This flexibility allows manufacturers to precisely tailor the slurry to their specific kiln conditions, ensuring optimal performance and efficiency.

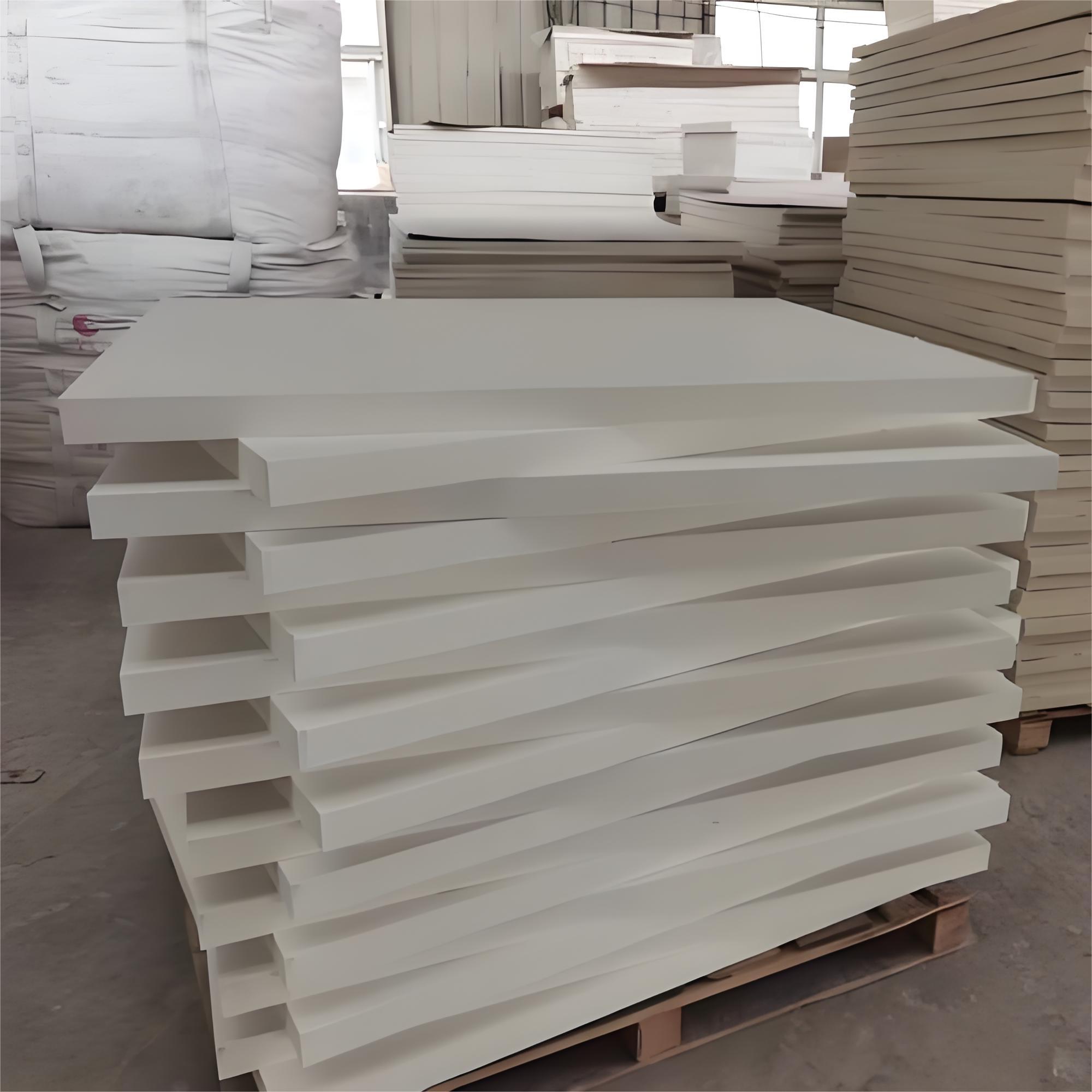

One of the key features of these ceramic slurries is their use of high - quality magnesia in the manufacturing process. This ensures excellent volume stability and durability, even under extremely high temperatures. In a case study of a large - scale steel manufacturing plant, after switching to Zhengzhou Rongsheng's ceramic slurries, the kiln lining's service life increased by 30%, reducing maintenance costs and downtime significantly.

Zhengzhou Rongsheng's ceramic slurries have obtained environmental management system certification, which is a testament to their compliance with international standards. This certification not only reflects the company's commitment to environmental protection but also provides customers with the confidence that the products are safe and reliable.

"The environmental management system certification of Zhengzhou Rongsheng's ceramic slurries gives us peace of mind. We can meet our production needs while also fulfilling our environmental responsibilities." - A European customer

Meeting international environmental standards also means that these products can be easily exported to various countries, opening up new market opportunities for global manufacturers.

In the glass manufacturing industry, the ceramic slurries are used to line the melting furnaces. Their high - temperature resistance and chemical stability prevent the corrosion of the furnace lining, ensuring a consistent quality of the glass products. In the cement industry, they help to improve the energy efficiency of the kilns by reducing heat loss.

For target customers, these ceramic slurries offer significant value. They can improve process efficiency by reducing energy consumption and increasing the service life of the kiln linings. Moreover, they enhance production safety by preventing potential accidents caused by lining failures.

| Benefits | Details |

|---|---|

| Process Efficiency | Up to 20% reduction in energy consumption |

| Production Safety | Minimized risk of lining failures |

| Cost Savings | Lower maintenance and replacement costs |

Zhengzhou Rongsheng's industrial kiln ceramic slurries are a game - changer in the high - temperature industrial process market. With their customizable compositions, superior performance, and environmental compliance, they offer a comprehensive solution for global manufacturers.

If you are looking for high - quality, customizable, and environmentally friendly industrial kiln ceramic slurries, don't miss out on this opportunity. Click here to learn more about Zhengzhou Rongsheng's products and how they can transform your industrial processes. We encourage you to leave your questions in the comments section below, and our experts will be happy to assist you!