In the field of refractory materials, silica bricks are highly sought - after for their excellent performance in high - temperature environments. Zhengzhou Rongsheng Refractory Materials Co., Ltd. has mastered the key technologies in silica brick manufacturing, ensuring high volume density and long - term durability.

The first step in silica brick manufacturing is raw material selection. High - quality silica sand is the primary raw material. It should have a high silica (SiO₂) content, usually above 96%. Impurities such as alumina (Al₂O₃), iron oxide (Fe₂O₃), and alkalis need to be strictly controlled. For example, the iron oxide content should be less than 1%. A customer in a steel plant once reported that using silica bricks made from low - impurity raw materials significantly improved the service life of their hot blast stoves. The right raw materials form the foundation for achieving a high volume density of over 2.85 g/cm³ in the final product.

The molding process has a direct impact on the density and structure of silica bricks. Zhengzhou Rongsheng uses advanced hydraulic presses to ensure uniform pressure distribution during molding. The pressure applied typically ranges from 150 to 200 MPa. This high - pressure molding helps to eliminate voids and increase the packing density of the raw materials. In a case study from a glass factory, silica bricks with high - pressure molding showed better resistance to thermal shock and mechanical stress, which are crucial factors for durability under high - temperature conditions.

Firing is a critical stage where the chemical and physical properties of silica bricks are finalized. The firing temperature for silica bricks usually ranges from 1350°C to 1450°C, and the firing time can last from 3 to 5 days. Precise temperature control during firing is essential. For instance, if the temperature is too low, the quartz in the bricks may not fully transform, resulting in lower density and poor durability. On the other hand, if the temperature is too high, the bricks may deform. In a large - scale power plant, proper firing control of silica bricks ensured stable operation of their hot blast stoves at temperatures between 1770°C - 2000°C.

After firing, strict quality inspections are carried out. Parameters such as volume density, porosity, compressive strength, and thermal conductivity are measured. Only products that meet the strict standards, such as a volume density of over 2.85 g/cm³, a compressive strength of more than 40 MPa, and a porosity of less than 20%, are allowed to enter the market. As one customer said in an evaluation: "The quality inspection process of Zhengzhou Rongsheng gives us full confidence in their silica bricks. We have never had any issues related to product quality in our long - term cooperation."

Zhengzhou Rongsheng's silica bricks have obtained international certifications such as CE and ISO. These certifications are not only a recognition of product quality but also an assurance of compliance with international standards. The company's products are trusted by over 2000 customers globally, which is a strong proof of its high - quality products and excellent customer service.

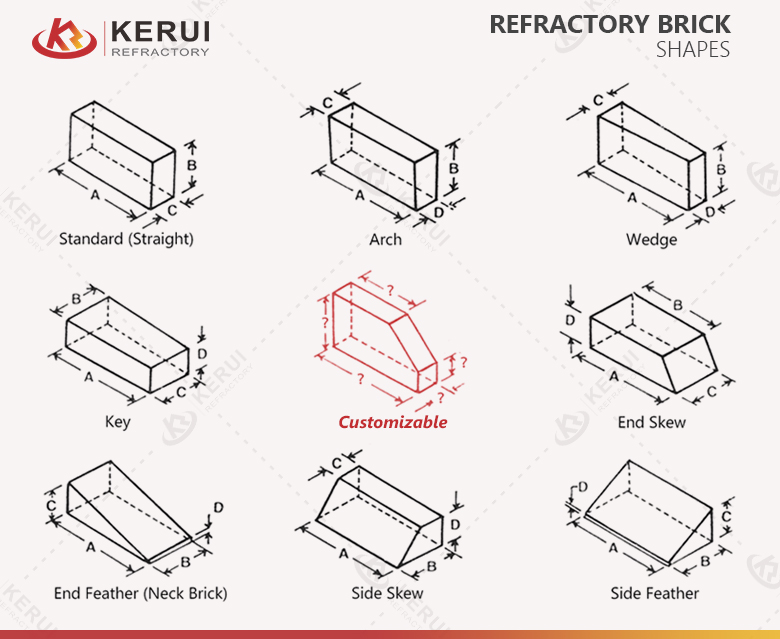

In addition to standard products, Zhengzhou Rongsheng also offers customization services. They can adjust the specifications, sizes, and performance parameters according to the specific needs of customers. For example, for a chemical plant with special high - temperature reaction conditions, the company customized silica bricks with a specific thermal expansion coefficient to meet the unique requirements of their equipment.

In conclusion, choosing the silica bricks from Zhengzhou Rongsheng means choosing a proven high - quality thermal solution. Their advanced manufacturing technologies, strict quality control, and customization capabilities make them a reliable partner for industrial customers in need of high - temperature protection solutions. Do you have specific high - temperature application scenarios? Contact us at CTA - URL for more information and customized solutions.