In high-temperature industrial production, refractory materials play a pivotal role. They are the silent guardians that ensure the smooth operation of various high-temperature processes. Among these, the high-quality corundum refractory balls produced by Zhengzhou Rongsheng Refractory Materials Co., Ltd. stand out with their remarkable performance and technical advantages.

Zhengzhou Rongsheng Refractory Materials Co., Ltd. is a national high-tech enterprise. With years of research and development and production experience, it has established a strong technical team and advanced production equipment. The company's brand influence is well - recognized in the industry. For example, over the past decade, it has provided refractory solutions for more than 500 high - temperature industrial enterprises around the world, which reflects its high - quality products and reliable service.

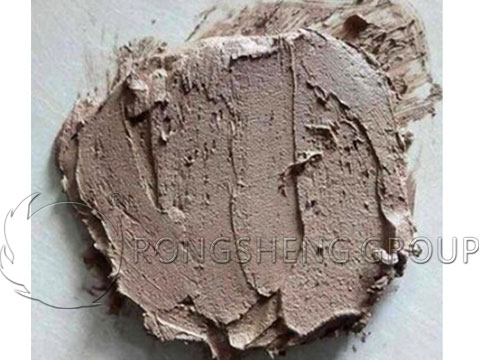

The corundum refractory balls produced by Zhengzhou Rongsheng have a high Al₂O₃ content, usually reaching over 90%. This high - content Al₂O₃ gives the refractory balls excellent refractoriness. For instance, it can withstand temperatures up to 1800°C without significant deformation, which is crucial for high - temperature industrial processes such as steelmaking and glass melting.

Thermal stability is another key advantage. The corundum refractory balls can maintain their physical and chemical properties under long - term high - temperature conditions. In actual use, they can work continuously at a high temperature of 1500°C for more than 300 days without obvious performance degradation, ensuring the long - term stability of the production process.

In high - temperature industrial environments, materials often face sudden temperature changes and chemical corrosion. The corundum refractory balls of Zhengzhou Rongsheng have excellent thermal shock resistance. They can withstand more than 500 rapid heating and cooling cycles without cracking. In terms of corrosion resistance, they can resist the erosion of various acidic and alkaline substances, which is very important for industries such as chemical and non - ferrous metal smelting.

| Advantage | Technical Data |

|---|---|

| Al₂O₃ Content | Over 90% |

| Maximum Withstand Temperature | 1800°C |

| Continuous Working Days at 1500°C | Over 300 days |

| Thermal Shock Resistance Cycles | Over 500 times |

Zhengzhou Rongsheng offers customized services. Different high - temperature industrial processes have different requirements for refractory materials. The company can customize corundum refractory balls according to the specific needs of customers, such as size, shape, and performance. This personalized solution can significantly improve the operational performance of high - temperature equipment. For example, a chemical plant required refractory balls with special corrosion - resistance requirements. Zhengzhou Rongsheng developed a customized product for it, which effectively solved the corrosion problem in the plant's high - temperature reaction process and improved production efficiency by 20%.

Many customers have given positive feedback on Zhengzhou Rongsheng's corundum refractory balls. A steelmaking enterprise in Europe said that after using these refractory balls, the service life of their high - temperature furnaces has been extended by 30%, and the frequency of equipment maintenance has been significantly reduced. Another glass manufacturing company in Asia reported that the use of these refractory balls has improved the quality of their glass products and reduced production costs by 15%.

Do you have any questions about our corundum refractory balls? Feel free to leave a comment below. If you are looking for high - quality refractory materials to improve your production stability and efficiency, don't miss the corundum refractory balls from Zhengzhou Rongsheng. Click here to learn more and make a wise choice for your high - temperature industrial production!