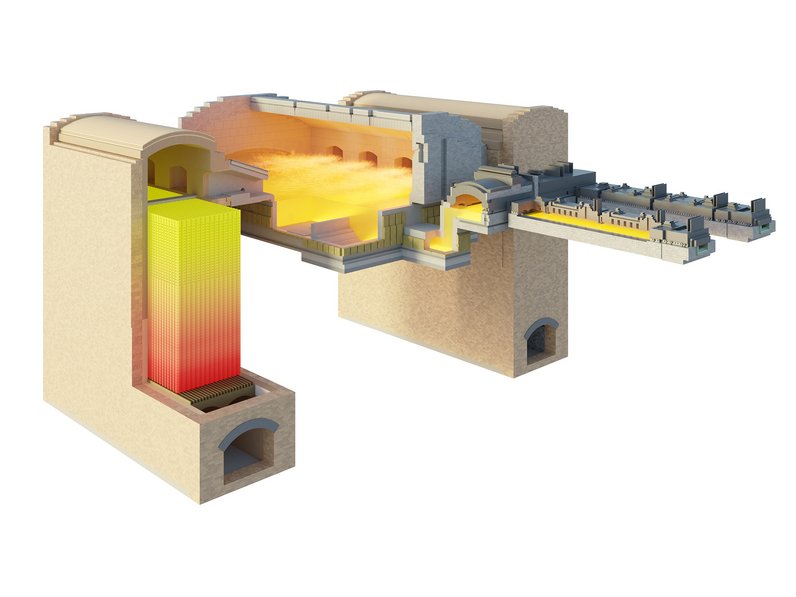

Industrial high-temperature furnaces face persistent energy consumption challenges, driving a demand for materials that not only withstand extreme thermal environments but also maximize energy retention. Zhengzhou Rongsheng Refractories Co., Ltd. addresses this critical need with their cutting-edge silicon carbide nitride bonded bricks, renowned for their exceptional thermal stability and remarkably low apparent porosity. These attributes directly contribute to enhanced energy efficiency and prolonged furnace lifespan, empowering industries such as steelmaking and ceramics to achieve process optimization and cost reduction.

The silicon carbide nitride bonded bricks exhibit a refractory temperature range surpassing 1700°C (3092°F), ensuring structural integrity under harsh thermal cycles. Their advanced bonding through silicon nitride formation provides outstanding mechanical strength coupled with superior thermal shock resistance, a key factor in industrial furnace applications where rapid temperature fluctuations are common.

Compared to traditional SiC bricks, these nitride bonded variants maintain a low apparent porosity below 10%, which drastically reduces gas and heat permeability. This specialized microstructure directly translates into better insulation performance, effectively minimizing heat loss through furnace walls. Industry tests reveal that adopting such bricks can decrease furnace energy consumption by up to 15%, a substantial saving on operational costs for continuous high-temperature processes.

| Property | Value Range | Industry Benefit |

|---|---|---|

| Refractoriness | > 1700°C (3092°F) | Endures extreme furnace environments |

| Apparent Porosity | < 10% | Improved insulation & reduced energy loss |

| Thermal Shock Resistance | High | Prolongs operational lifetime, minimizes downtime |

| Customizability | Tailored sizes & formulations | Fits precise furnace designs for maximal efficiency |

The nitride bonding process creates a dense, nearly pore-free microstructure. This low apparent porosity is crucial because pores and cracks in refractory bricks typically allow heat escape and chemical erosion from furnace atmospheres. By limiting these pathways, silicon carbide nitride bonded bricks maintain lower thermal conductivity, thus stabilizing internal temperatures and reducing the need for excessive fuel consumption.

Moreover, these bricks exhibit superior oxidation resistance at elevated temperatures, which is critical in aggressive furnace environments. The durable oxide layer formed protects the brick structure and extends maintenance intervals, thus indirectly contributing to energy savings through improved furnace uptime and reduced thermal cycling-induced wear.

Multiple industry leaders in steel manufacturing have reported up to 12% reductions in furnace energy consumption and 20% longer refractory service life after switching to Zhengzhou Rongsheng’s silicon carbide nitride bonded bricks. For example, in a continuous casting operation, the bricks' ability to sustain stable temperatures directly improved the metal quality and throughput.

Similarly, the ceramics industry benefits from these bricks’ thermal insulation and shock resistance, enabling kilns to operate at high efficiency with minimized energy waste. Custom brick configurations are designed to meet varying furnace geometries, ensuring a perfect seal that prevents thermal leakage.

Feedback from users emphasizes the reliability and consistency of the bricks in demanding environments. A leading steel plant’s production manager noted: "Since integrating these nitride bonded bricks, our furnace operations have seen remarkable energy savings and decreased refractory replacements, directly enhancing our production stability."

This credibility bolsters Zhengzhou Rongsheng’s reputation as a provider of innovative, sustainable refractory solutions.

For industrial operators aiming to optimize their thermal processes while controlling operational costs, the adoption of silicon carbide nitride bonded bricks represents a tangible path toward sustainability and efficiency enhancement. With proven energy-saving potential and robust performance, these bricks meet rigorous international standards and offer tailored solutions across metallurgical, ceramic, and other high-temp sectors.

Discover How Our Silicon Carbide Nitride Bonded Bricks Can Transform Your Furnace Efficiency Today