In high - temperature industries, the demand for efficient insulation materials has been on the rise steadily. As industrial processes become more complex and energy - efficient requirements become stricter, choosing the right insulation material is crucial for reducing energy consumption and improving production efficiency. High - alumina insulating bricks have emerged as an ideal solution in this context.

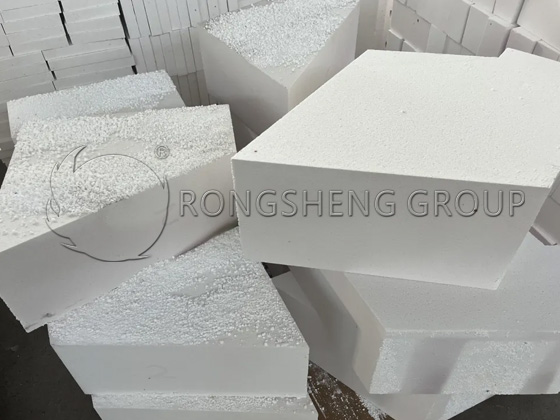

High - alumina insulating bricks are characterized by their high alumina content, typically with Al₂O₃ ≥ 48%. This high alumina content gives them excellent thermal insulation properties. The bricks have a lightweight and porous structure, which further enhances their heat - insulating capabilities. Their maximum service temperature can reach up to 1350℃, making them suitable for a wide range of high - temperature applications.

The technical principle behind these bricks lies in the physical and chemical properties of alumina. Alumina has a high melting point and low thermal conductivity. When used in the form of insulating bricks, it can effectively block the transfer of heat, reducing heat loss from high - temperature equipment.

The manufacturing process of high - alumina insulating bricks is a key factor in ensuring their quality. The raw materials are carefully selected and processed through a series of steps, including mixing, molding, and firing. During the firing process, strict temperature and time controls are maintained to ensure the formation of a stable crystal structure in the bricks.

Moreover, the products are produced under the ISO9001 quality management system. This international standard ensures that every stage of production, from raw material procurement to final product delivery, is strictly monitored and controlled. As a result, customers can be confident in the consistent quality of the high - alumina insulating bricks.

High - alumina insulating bricks have been widely used in industries such as glass ceramics, power, and boilers. In the glass ceramics industry, where high - temperature melting and forming processes are involved, these bricks can effectively reduce heat loss from furnaces, saving energy and improving the quality of glass products. For example, a glass ceramics factory reported a 15% reduction in energy consumption after replacing traditional insulation materials with high - alumina insulating bricks.

In the power industry, especially in power boilers, high - alumina insulating bricks can maintain high - temperature stability, ensuring the efficient operation of boilers. A power plant found that using these bricks improved the boiler's thermal efficiency by about 12%, which translated into significant cost savings over time.

In the boiler industry, high - alumina insulating bricks can withstand the harsh high - temperature and corrosive environments inside boilers. A boiler manufacturer reported that the service life of their boilers increased by 20% after using these bricks, reducing maintenance costs for customers.

Zhengzhou Rongsheng has over 20 years of R & D experience in the field of high - temperature insulation materials. Their long - term commitment to research and development has enabled them to continuously improve the performance of high - alumina insulating bricks. They have a professional R & D team that is constantly exploring new materials and manufacturing processes to meet the evolving needs of the market.

With their strong brand strength and innovation ability, Zhengzhou Rongsheng can provide customers with not only high - quality products but also customized solutions. Whether it's a small - scale industrial furnace or a large - scale power boiler, they can offer the most suitable high - alumina insulating bricks.

In conclusion, high - alumina insulating bricks are an excellent choice for high - temperature industries. Their high alumina content, excellent thermal insulation performance, and reliable quality make them a cost - effective solution for reducing energy consumption and improving production efficiency. If you are looking for a reliable thermal insulation solution for your high - temperature equipment, Zhengzhou Rongsheng's high - alumina insulating bricks are definitely worth considering. Click here to learn more about our high - alumina insulating bricks and start saving energy today!