In the high - temperature production industries such as steel and cement, managers, technical staff, and procurement officers are constantly seeking ways to ensure the stability and safety of equipment. They understand that any equipment failure in high - temperature environments can lead to significant production losses and safety hazards. For instance, in a steel plant, a breakdown of the furnace lining can halt the entire production line, causing delays and financial losses.

Magnesium - aluminum spinel refractory bricks offer several outstanding advantages. Firstly, they have a high refractoriness ranging from 1770°C to 2000°C. This wide range allows them to withstand extreme heat in various high - temperature industrial processes. Secondly, these bricks are made of high - purity materials, which ensures their chemical stability and durability. The purity of the materials can reach over 95%, reducing the risk of chemical reactions and wear in high - temperature environments.

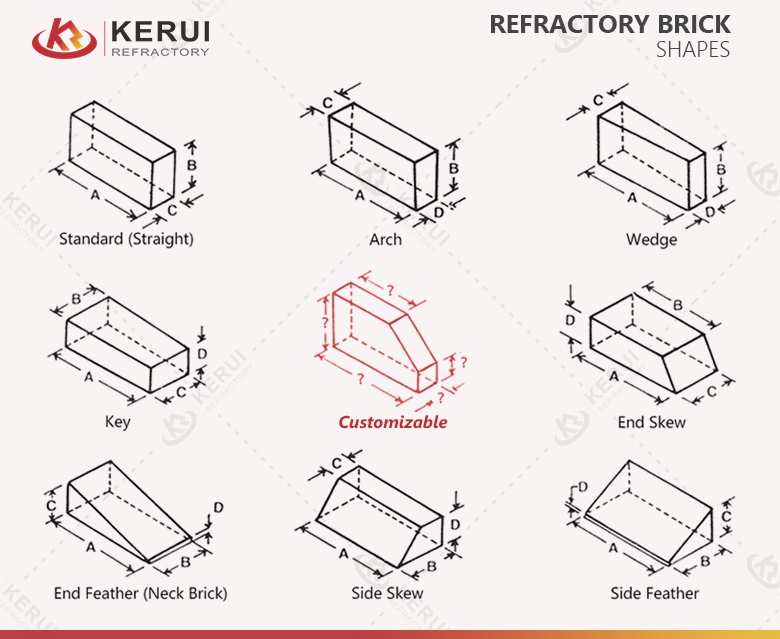

What's more, the composition of these refractory bricks can be customized. This feature enables them to be tailored to the specific needs of different industrial applications. For example, in a cement kiln, a customized refractory brick can be designed to resist the corrosive effects of cement clinker, thus extending the service life of the kiln lining. By using these refractory bricks, industries can also improve thermal efficiency. Studies have shown that using magnesium - aluminum spinel refractory bricks can reduce energy consumption by up to 15% and lower maintenance costs by 20% compared to traditional refractory materials.

In the steel industry, magnesium - aluminum spinel refractory bricks are used in furnaces, ladles, and converters. These bricks can withstand the high - temperature molten steel and slag, ensuring the smooth operation of the steel - making process. In the cement industry, they are applied in cement kilns, where they need to resist the high - temperature calcination process and the chemical corrosion of cement raw materials.

However, traditional refractory materials often fail to meet the long - term stability requirements in these harsh environments. The high - performance magnesium - aluminum spinel refractory bricks, on the other hand, can ensure the long - term stable operation of equipment in these industries, reducing the frequency of equipment shutdowns and maintenance.

A well - known steel company in Europe replaced its traditional refractory lining with magnesium - aluminum spinel refractory bricks. Before the replacement, the furnace lining needed to be repaired every 3 months, and the energy consumption was relatively high. After using the new refractory bricks, the service life of the furnace lining was extended to 12 months, and the energy consumption was reduced by 12%. This not only improved the safety of the production process but also brought significant economic benefits to the company.

Refractoriness refers to the ability of a refractory material to withstand high - temperature without melting or softening. Several factors can affect the performance of refractory materials, including chemical composition, density, and porosity. When purchasing refractory bricks, buyers should consider the specific requirements of their equipment, such as the maximum temperature, chemical environment, and mechanical stress. It is also recommended to choose products from reliable manufacturers with strict quality control systems.

The magnesium - aluminum spinel refractory bricks go through a strict testing process. They have obtained ISO standard certification, which significantly enhances the trustworthiness of the products. This certification ensures that the products meet international quality and safety standards. For buyers, choosing ISO - certified products means lower risks and more reliable performance.

If you are in the high - temperature production industries and are looking for reliable refractory solutions to ensure the stability and safety of your equipment, click here to learn more about our magnesium - aluminum spinel refractory bricks. We are committed to providing you with high - quality products and professional technical support.

Do you have similar needs in your industry? Share your specific scenarios with us, and we'll send you 3 case studies of solutions from the same industry.