In the high-temperature industries—such as steelmaking, cement production, and petrochemicals—choosing the right refractory cement isn't just about durability. It’s about ensuring continuous operation, minimizing downtime, and maximizing safety. At Zhengzhou Rongsheng Refractory Materials Co., Ltd., we’ve spent over 18 years refining our refractory cement formulations to meet the toughest global standards—and deliver real-world performance.

Many engineers assume that any "heat-resistant" material will do—but that’s where projects fail. Our data shows that standard mortars degrade after just 300 thermal cycles (at 1200°C), while our advanced refractory cement maintains structural integrity for over 1,200 cycles. That’s a 4x improvement in thermal shock resistance.

| Property | Standard Mortar | Rongsheng Refractory Cement |

|---|---|---|

| Compressive Strength (MPa) | 45 MPa | 85 MPa |

| Thermal Shock Resistance (cycles @ 1200°C) | ~300 | 1,200+ |

| Service Life (years) | 2–3 | 6–8 |

These aren’t just numbers—they’re results from field tests in aluminum smelters, kiln linings, and incinerators across Europe, Asia, and South America. We don’t design for specs—we design for survival.

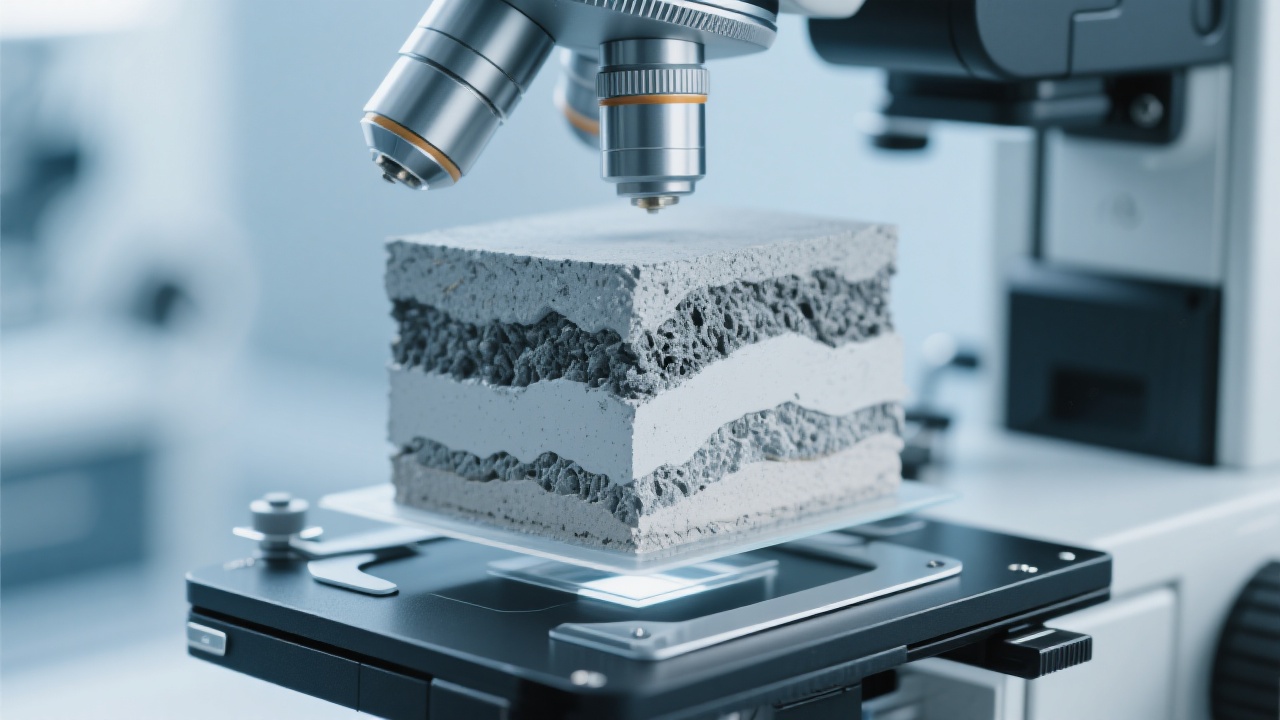

Our R&D team constantly pushes boundaries. With ISO 9001 (quality management) and ISO 14001 (environmental compliance) certifications, every batch of refractory cement undergoes rigorous testing—including chemical composition analysis, hot strength retention, and microstructure evaluation under SEM. This ensures consistency even when scaling up for large orders.

One size doesn’t fit all—especially in refractory applications. Whether you need a low-calcium version for ceramic kilns or a high-alumina blend for blast furnace linings, we tailor the formulation based on your process temperature, chemical exposure, and mechanical load. For example:

That’s what sets us apart—not just selling a product, but solving your specific problem.

Ready to upgrade your refractory system? Let’s talk about how our refractory cement can reduce maintenance costs and boost uptime in your facility.

Get Your Custom Refractory Cement Quote Today