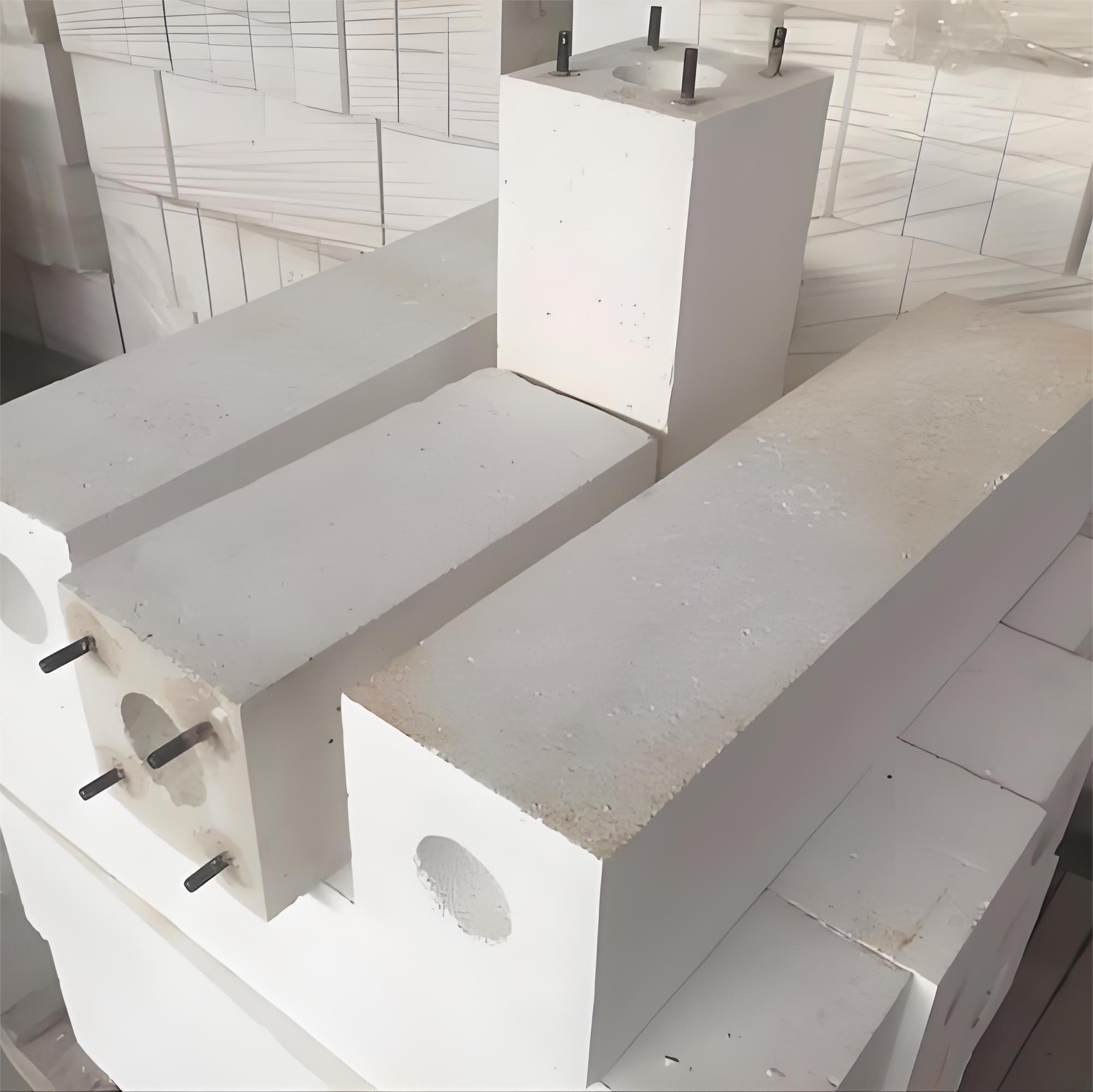

In the realm of high-temperature industrial operations, the choice of refractory materials is pivotal. Furnaces and kilns operating at extreme temperatures demand burner bricks that not only endure intense thermal stress but also improve operational efficiency and cost-effectiveness. One such advanced material gaining global recognition is the Corundum Mullite Burner Brick manufactured by Zhengzhou RongSheng Refractory Co., Ltd. With an impressive tolerance range of 1770°C to 2000°C and outstanding physical properties, these bricks are setting new benchmarks in furnace technology.

High-temperature industrial furnaces routinely expose materials to harsh conditions including rapid temperature cycling, chemical corrosion, and mechanical abrasion. Conventional refractory bricks often fall short. This is where Corundum Mullite Burner Bricks excel — combining the hardness and chemical stability of corundum (Al₂O₃) with the thermal shock resistance of mullite (3Al₂O₃·2SiO₂). Industries such as steelmaking, glass production, and cement manufacturing rely heavily on such bricks for sustained, trouble-free furnace operation.

| Feature | Description |

|---|---|

| High Refractoriness | Supports continuous operation between 1770°C and 2000°C, ensuring durability in ultra-high-temperature environments. |

| Low Apparent Porosity | Less than 18%, minimizing slag penetration and enhancing thermal insulation performance. |

| Customized Chemical Composition | Tailored to meet specific operational requirements, optimizing resistance to alkali and acidic slags. |

| Thermal Shock Resistance | Superior performance reduces repair frequency, thereby improving furnace uptime. |

| Mechanical Strength | High compressive strength supports structural stability during furnace operation. |

Since its inception, the Corundum Mullite Burner Brick has been deployed successfully across more than 70 countries spanning Asia, Europe, North America, and Africa. For example, a leading steel manufacturer in Germany reported a 15% increase in furnace thermal efficiency within six months of switching to these bricks. Similarly, a glass production facility in Brazil achieved a 20% reduction in refractory maintenance downtime, translating into significant operational savings.

These extensive deployments underscore not just the durability but also the versatility of the product across diverse high-temperature processes and chemical environments.

By minimizing furnace repair frequency and extending service life, the bricks contribute directly to lowering operational costs and enhancing throughput.

High-temperature industrial furnaces generally divide into batch and continuous types, each requiring specific brick properties for optimal performance. Corundum Mullite Burner Bricks are especially suited for the burner zones, where thermal intensity peaks and material degradation risk is highest.

When selecting refractory materials, decision-makers should weigh parameters like refractoriness under load (RUL), chemical compatibility with furnace atmospheres, and resistance to thermal cycling. Zhengzhou Rongsheng’s capability to customize chemical composition offers a tangible advantage here—ensuring bricks are engineered precisely for each application environment.

The journey behind Corundum Mullite Burner Brick began with rigorous material science research aimed at creating a product with both exceptional heat resistance and mechanical robustness. Multidisciplinary teams at Zhengzhou Rongsheng collaborated with furnace engineers worldwide to understand real-world challenges, iteratively improving formulations and kiln testing methodologies.

Thanks to advanced processing technologies and innovative binders, production achieves consistent brick density and uniform composition. This scientific approach is coupled with comprehensive technical support—from installation guidance to post-deployment monitoring—ensuring clients maximize the brick’s lifespan and performance.

For procurement officers and engineers aiming to elevate their high-temperature operations through cost-effective, reliable refractory materials, the Corundum Mullite Burner Brick is the proven choice.