With over two decades of specialized expertise in refractory materials, Zhengzhou RongSheng Refractory Co., Ltd. stands at the forefront of innovation and quality. As a nationally recognized high-tech enterprise, Rongsheng harnesses state-of-the-art automated and intelligent manufacturing lines to produce high-alumina bricks that consistently deliver superior performance in some of the world’s most extreme industrial environments.

The company’s investment in cutting-edge automation streamlines production, ensuring unmatched consistency across batches and reducing human error. Combining intelligent process control with rigorous quality checks, Rongsheng guarantees that each high-alumina brick achieves an optimal alumina content—typically exceeding 70%—which is critical for enhanced thermal and chemical resistance.

High-alumina bricks from Rongsheng exhibit exceptional resistance to thermal shock—a key parameter when materials are subjected to rapid temperature fluctuations in industries such as metallurgy, cement, and petrochemical processing. Field testing demonstrates these bricks withstand over 300 cycles of rapid heating and cooling without cracking or spalling, a benchmark that exceeds many industry standards.

Furthermore, the superior alumina content imparts excellent resistance to chemical corrosion caused by slags, alkalis, and acidic environments. In actual operations within steel converters and rotary kilns, Rongsheng bricks have reported up to 25% longer service life compared to conventional high-alumina bricks. This longevity translates directly into reduced maintenance downtime and cost savings.

Rongsheng’s high-alumina bricks carry multiple internationally recognized certifications, including ISO9001 for quality management, ISO14001 for environmental management, and CE certification for conformity with European standards. These accreditations reflect not only product excellence but also rigorous environmental and safety commitments, reassuring global customers of compliance and reliability.

Understanding the diverse requirements of the global high-temperature industry, Rongsheng offers customized refractory solutions that adapt to unique furnace designs and operating conditions. Their technical team collaborates closely with clients, providing feasibility analyses and on-site support to maximize brick performance.

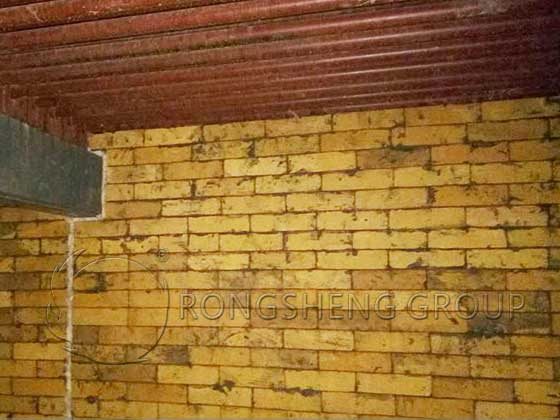

High Alumina Bricks in RS Factory" style="width:100%; border-radius:6px; margin:20px 0;">

High Alumina Bricks in RS Factory" style="width:100%; border-radius:6px; margin:20px 0;">

| Performance Metric | Rongsheng High-Alumina Brick | Industry Average |

|---|---|---|

| Alumina Content (%) | 72-85% | 65-75% |

| Thermal Shock Resistance (cycles) | > 300 | ~250 |

| Service Life (%) | +25% | Baseline |

A leading steel manufacturer in Europe adopted Rongsheng’s high-alumina bricks for their converter linings. Post-installation results indicated a 20% increase in furnace uptime due to fewer brick failures and lower maintenance needs. Similarly, a cement plant in South America reported a 15% reduction in kiln energy consumption, attributed to the superior insulation and thermal stability of Rongsheng products.

These cases underscore the bricks’ unmatched capability to endure fierce thermal cycles and chemically aggressive atmospheres, helping enterprises boost operational efficiency and extend asset life.

Equip your business with refractory materials trusted worldwide—engineered to withstand the harshest conditions and drive sustainable growth.