This guide is tailored for high - temperature industrial practitioners. In high - temperature industrial environments, such as in hot blast stoves, safety and stability are of utmost importance. The core requirements of these practitioners revolve around ensuring the long - term, reliable operation of their equipment while maintaining a high level of safety.

The silicon bricks in question are made from high - quality silica as the primary raw material. Silica has unique physical and chemical properties that make it an ideal choice for high - temperature applications. During the manufacturing process, advanced techniques are employed. The raw materials are carefully selected and proportioned, then go through processes like mixing, molding, and high - temperature firing. This meticulous manufacturing ensures the consistency and high quality of each brick.

Let's look at the physical performance data. The volume density of these silicon bricks is greater than 2.85 g/cm³. A high volume density indicates a more compact internal structure, which means better resistance to mechanical stress and thermal shock. In terms of temperature resistance, the silicon bricks can withstand temperatures ranging from 1770°C to 2000°C. This wide and high - end temperature range makes them suitable for use in extremely high - temperature environments like hot blast stoves. The practical value of these performance data is that they can ensure the long - term stability of hot blast stoves, reducing the frequency of maintenance and replacement, and thus saving costs for enterprises.

These silicon bricks hold both CE and ISO certifications. The CE certification indicates that the products meet the safety, health, and environmental protection requirements of the European Economic Area. The ISO certification, on the other hand, is a globally recognized standard for quality management systems. Having these two certifications provides strong quality assurance and industry recognition. It means that the products have been rigorously tested and meet international standards, which greatly enhances the credibility of the products in the eyes of customers.

"The CE and ISO certifications of these silicon bricks gave us great confidence. We know that we are using products that meet international quality standards, which is crucial for our high - temperature industrial operations." - A customer from a European high - temperature factory

To illustrate the reliability of these silicon bricks in extreme conditions, let's take a look at some real - world cases. In a steel plant in Asia, the hot blast stove was operating under extremely high - temperature and high - pressure conditions. The original refractory bricks were quickly damaged, affecting the normal operation of the stove. After replacing them with these silicon bricks, the hot blast stove has been running stably for more than two years without any major problems. This shows that the silicon bricks can maintain their performance and integrity even in the most demanding industrial environments.

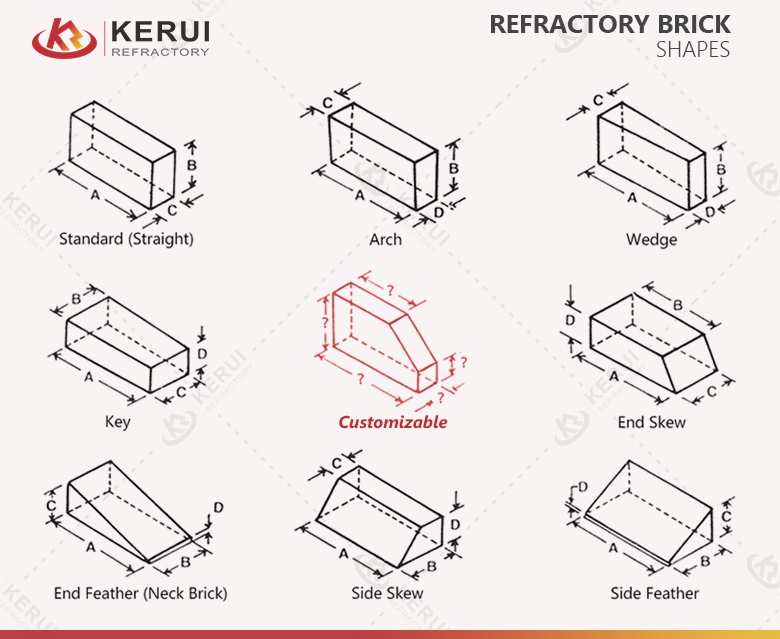

The company offers strong customization service capabilities. Different high - temperature industrial applications may have different requirements for the size, shape, and performance of refractory bricks. The company can provide customized solutions according to the specific needs of customers. Moreover, with a global service network, it can quickly respond to customer needs anywhere in the world. This reflects the company's professionalism and high - efficiency response, ensuring that customers can get timely support and services.

With over 2000 global customers already relying on these silicon bricks, it has become a trusted choice in the high - temperature industrial market. The combination of excellent physical performance, international certifications, real - world reliability, and strong customization and service capabilities makes it an ideal option for high - temperature industrial practitioners. If you want to learn more about the product details or have any purchasing inquiries, please click here to contact us. We are ready to assist you in making a wise purchasing decision.