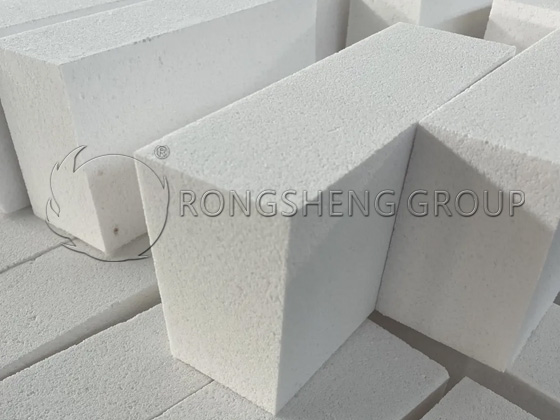

As global industries increasingly demand specialized refractory materials for extreme environments, Zhengzhou Rongsheng has positioned itself as a leading innovator. As a recognized national high-tech enterprise, Zhengzhou Rongsheng manufactures high-purity alumina bubble bricks with aluminum oxide content exceeding 90%, delivering exceptional durability and thermal resistance tailored to high-temperature applications. This product offers a superior refractory solution with temperatures ranging from 1770°C to 2000°C, reinforcing the company's reputation as a trustworthy partner for demanding projects worldwide.

One of Zhengzhou Rongsheng's standout features is the capability to customize alumina bubble bricks in both dimensions and shapes. This flexibility addresses unique project requirements across various high-temperature industries including metallurgy, glass manufacturing, cement production, and chemical processing. For instance, a steel plant in Eastern Europe opted for bespoke bricks tailored to their rotary kiln design, which significantly enhanced thermal efficiency and reduced downtime by 12% compared to conventional refractory materials.

Another case involved a glass factory in Southeast Asia where conventional refractory bricks failed under irregular thermal cycling. Zhengzhou Rongsheng’s tailored alumina bubble bricks, precisely engineered to fit complex furnace profiles, increased operational lifespan by 18% and improved safety margins without compromising insulation performance.

Zhengzhou Rongsheng’s alumina bubble bricks achieve an ultra-lightweight profile combined with high mechanical strength due to their advanced microstructure. The product exhibits a remarkably low thermal conductivity of approximately 0.16 W/m·K at operating temperatures, substantially outperforming traditional dense firebricks whose conductivity values approach 1.2 W/m·K under similar conditions.

Such low thermal conductivity provides excellent insulation, reducing heat losses and improving energy efficiency in furnace operations. Coupled with a high refractory temperature threshold up to 2000°C, these bricks withstand thermal shock and chemical corrosion better than many market alternatives, which often degrade under fluctuating high temperatures.

| Parameter | Zhengzhou Rongsheng Alumina Bubble Brick | Typical Dense Firebrick |

|---|---|---|

| Alumina Content | > 90% | 50-70% |

| Maximum Service Temperature | 2000°C | 1650°C - 1750°C |

| Thermal Conductivity (at 1000°C) | 0.16 W/m·K | 1.0 - 1.2 W/m·K |

| Bulk Density | 0.8 - 1.1 g/cm³ | 2.0 - 2.5 g/cm³ |

The production of alumina bubble bricks at Zhengzhou Rongsheng is fully automated through intelligent production lines, ensuring consistent product quality with minimal variation. These bricks meet or exceed international ceramics and refractory material standards including ISO 9001 quality management certification, ASTM C799 (Standard Test Method for Refractoriness under Load of Fireclay and High Alumina Bricks), and other relevant industrial benchmarks.

Compared to many generic alumina bricks available in the global market, Zhengzhou Rongsheng’s product stands out for its customization ability, superior thermal insulation, and long-term mechanical stability—attributes critical for maximizing operational uptime and reducing maintenance costs in high-temperature processing environments.

For engineers and procurement managers looking for trusted refractory materials that combine advanced technology, material excellence, and flexible design capabilities, Zhengzhou Rongsheng’s alumina bubble bricks offer a compelling solution. Their balance of light weight, high alumina purity, and customizable forms caters precisely to the evolving demands of modern high-temperature industries.

To harness the benefits of reliable refractory materials proven in diverse industrial applications globally, prospective buyers are encouraged to engage directly with Zhengzhou Rongsheng for detailed engineering consultations and tailored project solutions.

Ready to Enhance Your High-Temperature Operations?

Contact Zhengzhou Rongsheng today to explore customized alumina bubble brick solutions engineered specifically for your industrial needs. Elevate your project’s performance with proven expertise and unparalleled product quality.

Get in Touch Now