In the demanding landscape of industrial manufacturing, materials that deliver consistent thermal stability and mechanical integrity are essential. Rongsheng High-Performance Refractory Castables, developed by Zhengzhou RongSheng Refractory Co., Ltd., have gained widespread recognition among global industrial players for their exceptional quality and tailored solutions. This article highlights the core attributes of Rongsheng castables, their application success in power generation and refining sectors, and firsthand customer insights that confirm their reliability and effectiveness.

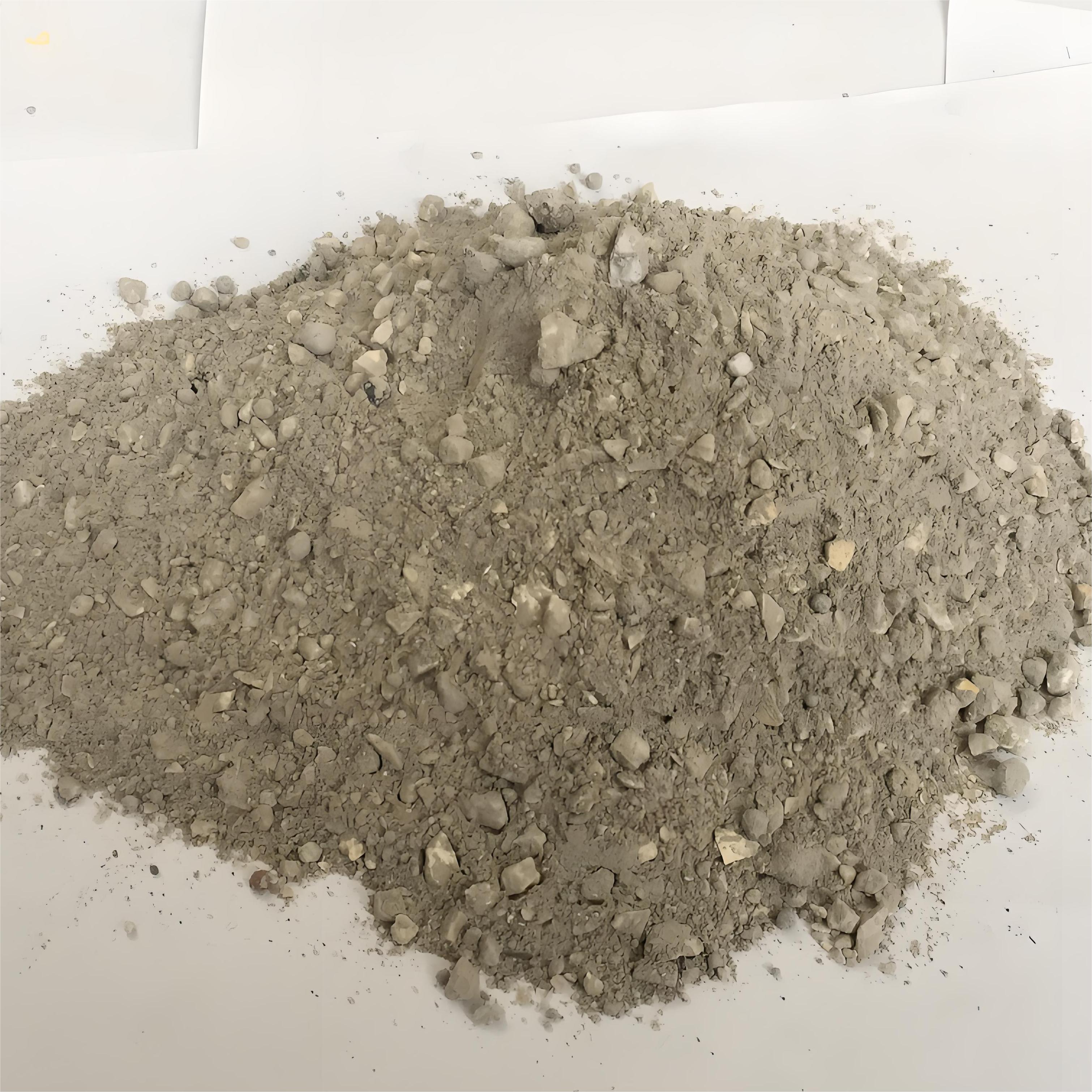

As a recognized National High-Tech Enterprise, Zhengzhou Rongsheng brings cutting-edge intelligent automation processes to refractory castable production. Their proprietary manufacturing techniques enable precise customization of silica (SiO2) content, while achieving remarkably high alumina (Al2O3) concentrations — up to 83%. This high alumina level ensures superior heat resistance and structural stability essential for diverse industrial applications.

Integral to global acceptance, Rongsheng's refractory castables comply with key international certification standards, facilitating their export to over 70 countries worldwide. The company's commitment to quality and innovation solidifies their position as a front-runner in refractory material solutions.

Rongsheng's refractory castables feature an optimized chemical profile tailored to the demanding environments of industrial furnaces and reactors. The adjustable SiO2 content allows customization to specific thermal and chemical conditions, maximizing performance for each unique application. High Al2O3 content up to 83% directly contributes to enhanced melting point and abrasion resistance, critical for extending operational lifespan.

refractory castables in industrial settings" style="width: 100%; margin: 20px 0; border-radius: 6px;">

refractory castables in industrial settings" style="width: 100%; margin: 20px 0; border-radius: 6px;">

This advanced formula yields remarkable thermal stability and structural integrity, even under rapid temperature fluctuations, reducing maintenance cycles and unplanned downtime.

Among the most challenging industrial environments, power plant boilers and refinery catalytic cracking units demand durable refractory linings to withstand extreme temperatures and chemical corrosion.

In multiple thermal power plants, Rongsheng’s refractory castables have been applied to boiler linings, evidencing exceptional resistance to slag erosion and thermal shock. Customers reported up to a 25% increase in refractory service life compared to conventional materials, significantly reducing scheduled maintenance costs.

Similarly, in refining operations, the castables’ tailored chemistry provides excellent protection for catalytic cracking units, resisting catalytic poisons and mechanical abrasion. A leading refinery in Asia confirmed improved operational stability and lowered downtime attributable directly to Rongsheng’s materials.

refractory castables applied in boiler lining maintenance" style="width: 100%; margin: 20px 0; border-radius: 6px;">

refractory castables applied in boiler lining maintenance" style="width: 100%; margin: 20px 0; border-radius: 6px;">

Mr. Li Wei, Maintenance Manager at a major power generation company, shared:

"Since integrating Rongsheng’s high-performance refractory castables, our boiler linings have demonstrated remarkable durability under extreme operating conditions. The reduced downtime and lower replacement frequency translate to significant cost savings and improved plant reliability."

Similarly, Ms. Anya Petrov, Operations Director at a leading refinery, noted:

"Rongsheng’s ability to customize the castables’ chemical composition has been a crucial factor in withstanding our process environment’s aggressive conditions. Their product stability and performance have exceeded our expectations."

Refractory castables in catalytic cracking unit protection" style="width: 100%; margin: 20px 0; border-radius: 6px;">

Refractory castables in catalytic cracking unit protection" style="width: 100%; margin: 20px 0; border-radius: 6px;">

Compared to traditional refractory castables, Rongsheng’s products demonstrate:

| Feature | Rongsheng Castables | Conventional Castables |

|---|---|---|

| Alumina Content (Al₂O₃) | Up to 83% | Typically 45-60% |

| Thermal Stability | Excellent under rapid temperature changes | Moderate, prone to thermal cracking |

| Customization | SiO₂ content customizable to process needs | Limited flexibility |

| Compliance | Meets multiple international certifications | Varies by manufacturer |

These advantages cumulatively contribute to longer refractory life span, reduced operational expenditures, and enhanced process safety.

Ready to enhance the reliability and efficiency of your industrial operations? Connect with Rongsheng today to discover how our high-performance refractory castables can be customized for your specific application needs. Experience unparalleled quality trusted by global leaders in power generation and refining.