In modern industrial production, minimizing energy waste and maximizing heat retention have become critical focuses for enterprises aiming at cost-effective and sustainable growth. Zhengzhou Rongsheng Refractory Materials Co., Ltd. offers a breakthrough solution: their 1260°C standard high-temperature ceramic fiber paper. This innovative product has demonstrated outstanding performance in real-world manufacturing environments, enabling clients to achieve significant energy savings and operational efficiency improvements.

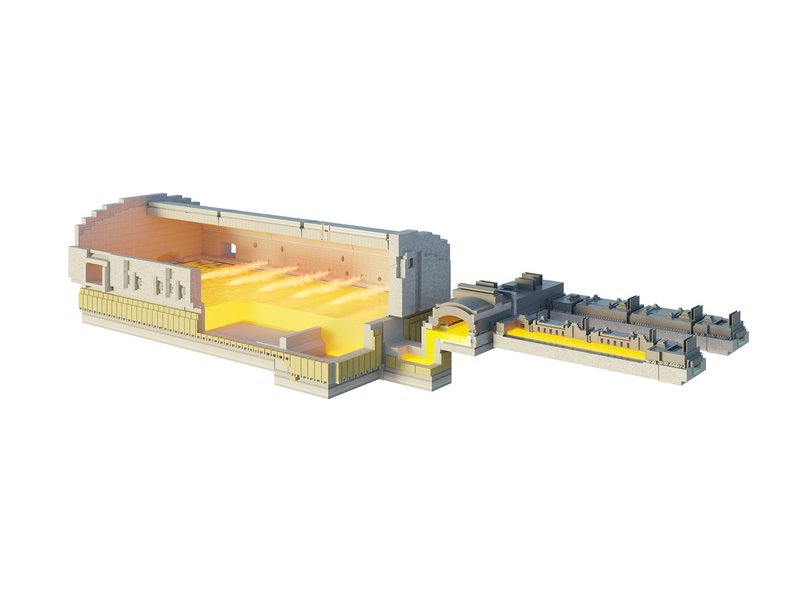

Crafted from top-grade alumina-silica fibers, the ceramic fiber paper withstands continuous exposure up to 1260°C without degradation. Its remarkable low thermal conductivity—measured at approximately 0.12 W/m·K at 1000°C—greatly reduces heat loss, compared to conventional insulation materials that typically exhibit conductivity values above 0.20 W/m·K under similar conditions. This superior insulation translates directly into substantial energy savings, especially in high-temperature processing lines such as metallurgical furnaces, heat treatment units, and kiln systems.

| Key Property | Value | Industry Benchmark |

|---|---|---|

| Max Operating Temperature | 1260°C (2300°F) | Up to 1200°C |

| Thermal Conductivity @ 1000°C | 0.12 W/m·K | 0.20+ W/m·K |

| Thickness Range | 1mm to 10mm Customizable | Fixed Sizes |

Understanding that every industrial setup comes with unique process requirements and spatial constraints, Rongsheng provides custom-sizing options for their ceramic fiber paper. This adaptability ensures seamless integration into existing insulation assemblies, reducing installation time and enhancing operational reliability. Typical client sectors benefiting from this customization include:

A leading metal forging enterprise recently revamped its heat treatment line insulation using Rongsheng’s ceramic fiber paper. The upgrade led to a 15% reduction in fuel consumption during peak operation hours, equating to annual savings surpassing 50,000 USD. Moreover, temperature uniformity improved by 10%, directly enhancing product quality consistency. These measurable benefits underscore how deploying the right insulation materials translates to tangible operational gains.

Beyond superior product specifications, Zhengzhou Rongsheng Refractory Materials emphasizes client partnership. Their full-service approach includes technical consultation, on-site application guidance, and post-installation support, ensuring seamless transition and optimal performance. All products carry international quality certifications such as ISO 9001, ASTM C892 compliance for ceramic fiber products, and environmental safety verifications, reassuring clients of reliability and sustainability.

If your enterprise strives to reduce operational costs, enhance furnace lifespan, and embrace greener production methods, Zhengzhou Rongsheng’s 1260°C ceramic fiber paper offers a compelling solution. With customizable options, verified performance metrics, and trusted customer outcomes, it stands as an indispensable asset in modern industrial insulation strategies.

Discover How Our Ceramic Fiber Paper Can Transform Your Production Efficiency – Contact Us Today!