Industrial furnaces operate under extreme thermal conditions—often exceeding 1200°C—making effective heat management critical for both energy efficiency and operational safety. Poor insulation leads to significant heat loss, increased fuel consumption, and accelerated equipment degradation. That’s where customized ceramic fiber boards from Rongsheng Refractories come in.

Rongsheng’s ceramic fiber boards are engineered for high-temperature environments, with a maximum service temperature of up to 1430°C. At 1000°C, they maintain an impressively low thermal conductivity of just 0.19 W/m·K, significantly outperforming traditional insulating materials like mineral wool or brick. This means less heat escapes, reducing energy costs by up to 25% in real-world applications across steel, glass, and cement industries.

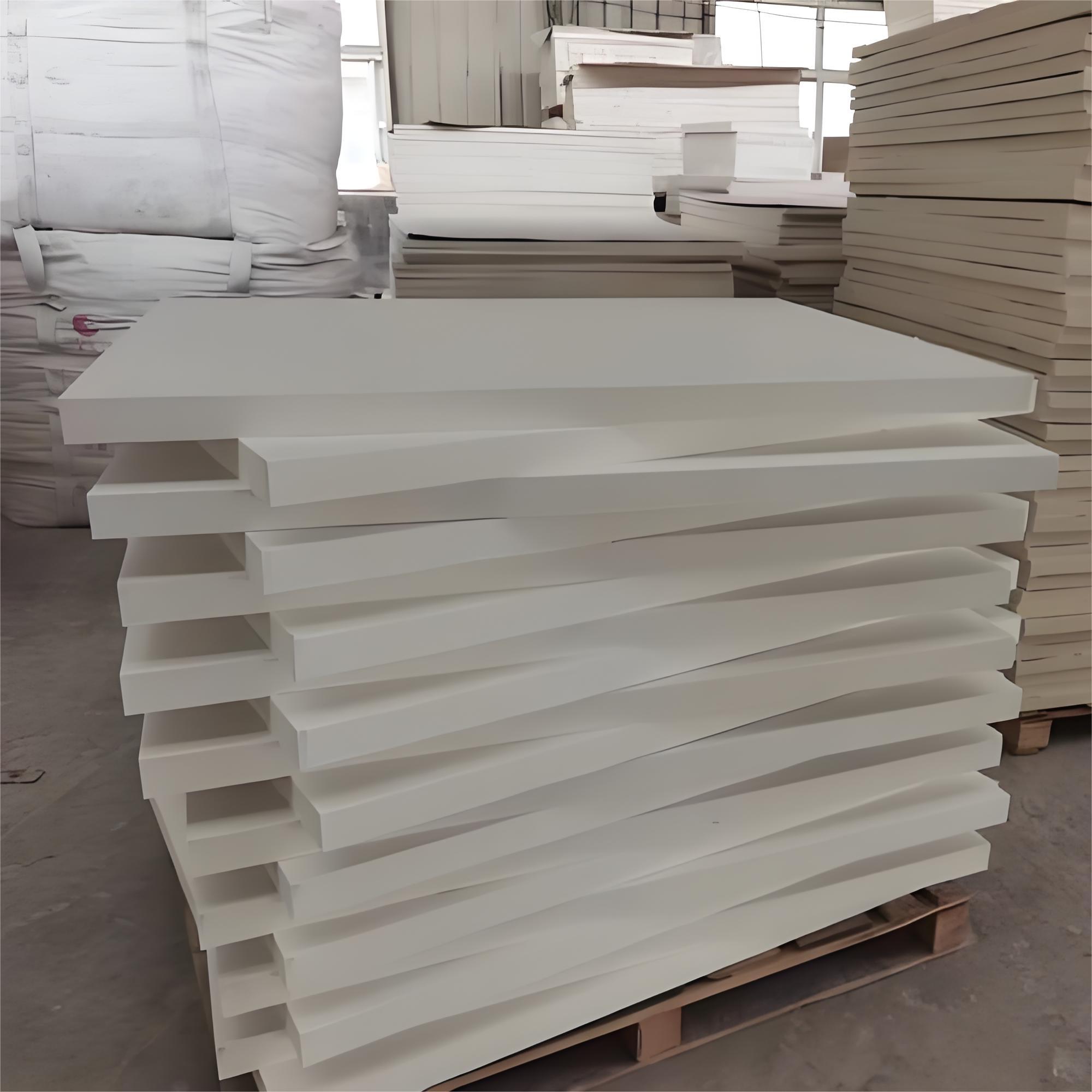

Every industrial furnace has its own geometry, operating cycle, and thermal load profile. A one-size-fits-all approach doesn’t work. Rongsheng offers full customization in thickness (from 25mm to 200mm) and dimensions (up to 1200x600mm per panel), ensuring perfect fit for complex refractory structures such as kilns, ovens, and ladles.

“We needed precise insulation for our continuous annealing line in Germany. Rongsheng’s team worked with us to design custom 150mm-thick panels that matched our exact furnace wall curvature. Since installation, our gas usage dropped by 18%.” – Markus L., Plant Manager, Steelworks GmbH, Germany

With ISO 9001 and CE certifications, Rongsheng ensures consistent quality across all production batches. Over 2,000+ factories worldwide have adopted our solutions—from foundries in India to ceramic plants in Saudi Arabia—proving reliability in diverse climates and regulatory environments.

These aren’t just numbers—they translate into real benefits: longer furnace life, fewer maintenance downtimes, and safer working conditions. For decision-makers focused on ROI, this is more than material—it’s a strategic upgrade.

Get your free technical consultation today—no obligation, no spam. Let us help you select the ideal ceramic fiber board size and thickness tailored to your specific furnace application.

Download Our Free Customization Guide Now