In the realm of high-temperature equipment sealing, the challenges are both complex and costly. Traditional sealing materials often fall short, leading to significant energy waste and potential equipment damage. This article delves into the innovative solution provided by Zhengzhou Rongsheng Refractory Materials Co., Ltd. - high-performance ceramic fiber ropes, and explores their applications and advantages in high-temperature equipment sealing.

High-temperature equipment, such as furnaces, kilns, and boilers, operates under extreme conditions. Traditional sealing materials, like asbestos and rubber, struggle to withstand the high temperatures and harsh chemical environments. As a result, these materials degrade quickly, causing energy to leak out and leading to increased energy consumption. In fact, studies have shown that improper sealing can result in energy losses of up to 20% in some industrial applications. Moreover, the deterioration of traditional materials can also lead to equipment malfunctions, increasing maintenance costs and downtime.

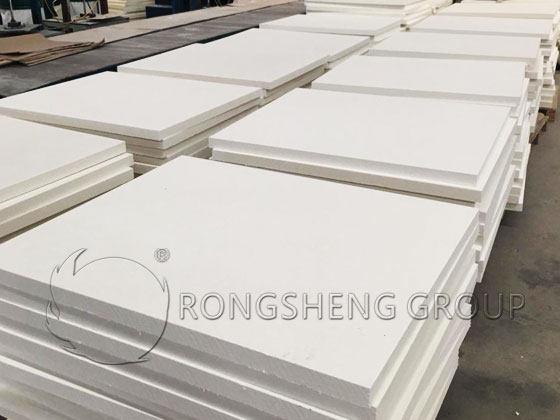

Zhengzhou Rongsheng Refractory Materials Co., Ltd. has developed a revolutionary solution - high-performance ceramic fiber ropes. These ropes are manufactured using advanced technology, enabling them to withstand temperatures of up to 1260°C, far exceeding the capabilities of traditional sealing materials. The manufacturing process involves spinning high-quality ceramic fibers into a strong and flexible rope structure, ensuring its durability and reliability in high-temperature environments.

One of the key advantages of ceramic fiber ropes is their excellent chemical resistance. They can resist a wide range of chemicals, including acids, alkalis, and solvents, making them ideal for use in chemical processing plants and other industrial settings where exposure to corrosive substances is common. This resistance ensures that the ropes maintain their integrity over time, reducing the need for frequent replacements.

Another significant benefit is their low thermal conductivity. With a thermal conductivity as low as 0.05 W/(m·K) at 1000°C, ceramic fiber ropes can effectively reduce heat transfer, minimizing energy loss. This not only helps to save energy but also improves the overall efficiency of high-temperature equipment.

| Features | Ceramic Fiber Ropes | Ordinary Sealing Materials |

|---|---|---|

| Maximum Temperature Resistance | 1260°C | Below 800°C |

| Chemical Resistance | Excellent | Poor |

| Thermal Conductivity | As low as 0.05 W/(m·K) at 1000°C | High |

Zhengzhou Rongsheng Refractory Materials Co., Ltd. understands that different industries have unique requirements. Therefore, they offer a wide range of customization options for their ceramic fiber ropes. Customers can choose from various diameters, lengths, and densities to meet their specific needs. This flexibility allows for optimal performance in different high-temperature applications.

With over 2000 satisfied customers in more than 70 countries, the company has accumulated rich experience in serving global clients. Their products are certified to meet international standards, ensuring their quality and reliability. For example, a customer in the steel industry reported a significant reduction in energy consumption after replacing their traditional sealing materials with Rongsheng's ceramic fiber ropes. The ropes' ability to maintain a tight seal even at high temperatures helped to improve the efficiency of their furnaces and reduce maintenance costs.

In conclusion, high-performance ceramic fiber ropes offer a superior solution for high-temperature equipment sealing. Their excellent heat resistance, chemical resistance, and low thermal conductivity make them an ideal choice for industries looking to improve energy efficiency and reduce equipment downtime. If you are facing challenges with high-temperature equipment sealing, don't hesitate to contact us for more information and a customized solution.