In the demanding sectors of ceramics and glass manufacturing, furnace integrity and insulation efficiency are pivotal for optimizing productivity and reducing operational costs. Zero-expansion silica bricks, developed with cutting-edge manufacturing techniques by Zhengzhou Rongseng Refractory Materials Co., Ltd., have emerged as indispensable components to address these challenges. This article delves into the superior features of zero-expansion silica bricks, their critical roles in industrial applications, and the technological advancements that make them a preferred choice for over 2000 satisfied customers worldwide.

Furnaces operating in ceramics and glass production demand refractory materials that can withstand high temperatures while maintaining dimensional stability. Unlike conventional silica bricks that may crack or deform due to thermal expansion, zero-expansion silica bricks exhibit near-zero volumetric changes across a broad temperature spectrum, ensuring structural integrity and longevity of refractory linings. This stability is crucial for industries where even slight dimensional changes can compromise product quality and safety.

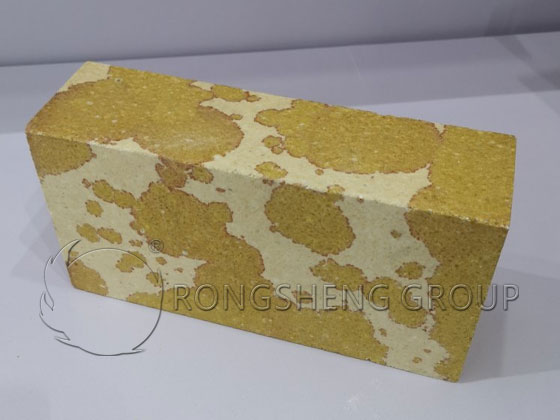

Durability: Zero-expansion silica bricks feature exceptional refractory properties, including resistance to chemical corrosion and mechanical wear, resulting in superior lifespan under harsh industrial conditions.

Thermal Stability: These bricks maintain dimensional stability when exposed to temperatures ranging from ambient up to 1650°C. Studies indicate a linear thermal expansion coefficient approaching zero, effectively mitigating the risks of cracking.

Low Porosity: The manufacturing process ensures a low porosity threshold, typically below 12%, minimizing the penetration of slags and gases, which improves insulation performance and reduces thermal conductivity.

Zhengzhou Rongseng’s proprietary manufacturing methodology integrates precision raw material selection, controlled calcination, and innovative sintering techniques to produce highly consistent zero-expansion silica bricks. The process includes:

With a portfolio exceeding 2000 clients globally, zero-expansion silica bricks have consistently demonstrated their value in enhancing furnace insulation performance, thereby increasing energy efficiency and reducing maintenance downtime. For example, a leading ceramics manufacturer reported a 15% reduction in fuel consumption and prolonged furnace lining lifespan by 25% after adopting these bricks. The consistency in performance across diverse industrial facilities underscores their versatility and reliability.

Selecting refractory materials is a strategic decision that influences operational costs and product quality. Zhengzhou Rongseng’s zero-expansion silica bricks deliver:

"Zero-expansion silica bricks have transformed our furnace maintenance strategy with their unparalleled durability and thermal stability, enabling us to increase furnace uptime and product consistency." – Industry Expert, Zhengzhou Ceramics Plant