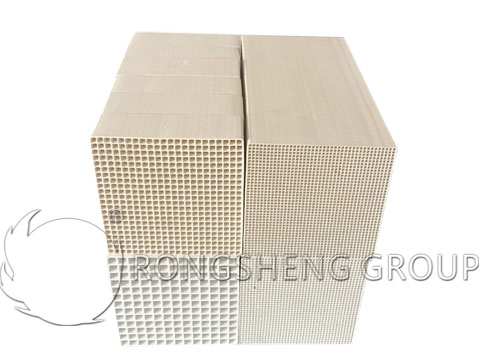

In the high - temperature industrial environment, the demand for reliable refractory materials is crucial. Zhengzhou Rongsheng Refractory Materials Co., Ltd., a national high - tech enterprise, has developed an innovative high - temperature resistant ceramic slurry for industrial kilns, which stands out with its unique composition customization technology.

The high - temperature resistant ceramic slurry developed by Zhengzhou Rongsheng contains a variety of components such as SiO2, Al2O3, MgO, CaO, CrO, and SiC. This flexibility in composition customization is a significant selling point. Different high - temperature processes in industrial kilns have distinct requirements. For example, in some steel - making kilns, a higher proportion of Al2O3 may be needed to enhance the refractoriness, while in non - ferrous metal smelting kilns, SiC might be crucial for improving thermal conductivity.

By precisely adjusting the proportion of these components, the slurry can be tailored to meet the specific needs of various high - temperature processes. According to research, customized ceramic slurries can improve the efficiency of high - temperature processes by up to 20% compared to standard products.

The high - temperature resistant ceramic slurry from Zhengzhou Rongsheng can withstand extremely high temperatures. It can maintain its structural integrity at temperatures up to 1800°C. This high - temperature resistance is mainly due to the stable chemical properties of its components. For instance, MgO has a high melting point and can effectively resist the erosion of high - temperature molten materials.

In addition to high - temperature resistance, the slurry also has excellent volume stability. During the heating and cooling cycles in industrial kilns, many materials will expand or contract, which may lead to cracking and damage. However, this ceramic slurry has a low coefficient of thermal expansion, ensuring its volume remains relatively stable. In practical applications, after 100 heating - cooling cycles, the volume change of the slurry is less than 1%, which is far superior to many similar products in the market.

The durability of the high - temperature resistant ceramic slurry is another remarkable feature. It has strong resistance to chemical corrosion from molten metals, slag, and gases in the high - temperature environment of industrial kilns. In a copper - smelting plant, the ceramic slurry lining the kiln wall has a service life of up to 3 years, significantly reducing the frequency of kiln maintenance and replacement, and thus saving production costs for enterprises.

| Performance Indicator | Value |

|---|---|

| Maximum Temperature Resistance | 1800°C |

| Volume Change after 100 Cycles | <1% |

| Service Life in Copper - smelting Kiln | 3 years |

The high - temperature resistant ceramic slurry has obtained international standard certifications, which is a guarantee of its quality and performance. These certifications ensure that the product meets the strict requirements of the international market. Moreover, the product is environmentally compliant. It does not contain harmful substances such as heavy metals in excessive amounts, which is in line with the current global trend of environmental protection.

For enterprises seeking high - temperature solutions for industrial kilns, Zhengzhou Rongsheng's high - temperature resistant ceramic slurry is an ideal choice. Its composition customization technology, excellent performance, and international certification make it a reliable partner for efficient production.

Are you looking for a high - quality high - temperature resistant ceramic slurry for your industrial kiln? Click here to learn more about our product and find the perfect solution for your high - temperature process!

We encourage you to leave your questions and comments below. Our experts will be happy to answer them and help you better understand the product.