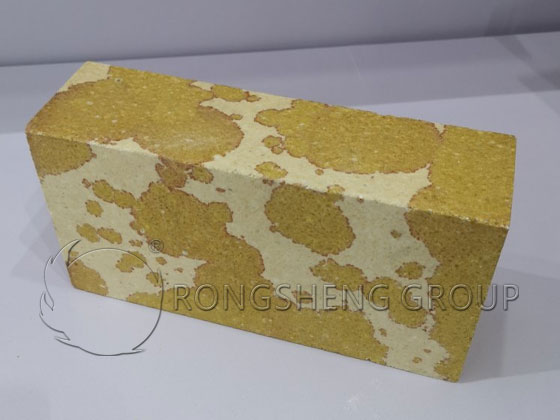

In high-temperature industrial applications such as ceramics and glass manufacturing, the integrity and efficiency of furnace linings are paramount. Zero-expansion silica bricks developed by Zhengzhou RongSheng Refractory Co., Ltd. offer an advanced refractory solution tailored specifically for these demanding environments. These bricks stand out due to their exceptional refractory performance, remarkable thermal stability, and notably low porosity, which collectively enhance furnace insulation, durability, and energy efficiency.

Zero-expansion silica bricks are designed to exhibit near-zero volumetric expansion under high temperatures, a characteristic critical to preventing thermal shock and mechanical stresses during operation cycles. Their heat resistance typically exceeds 1700°C, with a dilation rate close to 0% between ambient temperature and peak service temperatures, ensuring dimensional stability. This is a game-changer in the ceramics and glass industries where fluctuating thermal loads can severely impair furnace lining longevity.

“The zero-expansion silica bricks from Zhengzhou Rongsheng demonstrate less than 0.01% linear expansion at 1600°C, significantly reducing the risk of brick spalling and structural failure within glass kilns.” — Industrial Furnace Materials Journal

Porosity is a vital factor directly influencing heat insulation and mechanical robustness of refractory materials. The zero-expansion silica bricks produced by Rongsheng typically register porosity values below 12%, remarkably limiting gas permeability and heat loss. Consequently, industrial furnaces experience improved energy conservation and reduced maintenance intervals. A dense microstructure also translates to enhanced resistance against chemical corrosion and slag infiltration.

| Property | Typical Value | Industry Benchmark |

|---|---|---|

| Maximum Service Temperature | 1700°C+ | >1650°C |

| Linear Thermal Expansion | <0.01% (up to 1600°C) | 0.05% - 0.1% |

| Apparent Porosity | <12% | 15% - 20% |

Zhengzhou Rongsheng employs proprietary manufacturing technologies to produce zero-expansion silica bricks. Their process begins with carefully selected raw silica materials exhibiting high purity and uniform particle size distribution. Precision refining and controlled calcination remove impurities and stabilize the silica phase, preventing volume changes during firing. The bricks undergo isostatic pressing to achieve a dense, homogeneous structure, followed by the slow firing process that consolidates the microstructure while maintaining near-zero thermal expansion.

This approach results in bricks possessing minimal internal stresses and uniform chemical bonding, characteristics that minimize cracking risk and extend service life in severe industrial environments.

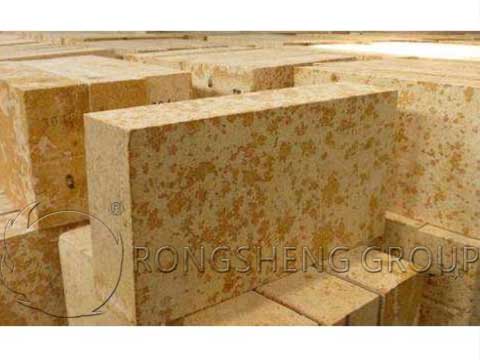

The application of zero-expansion silica bricks by Rongsheng in furnaces across the ceramics and glass sectors has been widely validated. With more than 2000 clients globally adopting these products, customer feedback consistently highlights improved furnace insulation efficiency, prolonged service intervals, and reduced operational downtime.

For example, a leading glass manufacturer reported a 15% reduction in fuel consumption after retrofitting their glass kiln with Rongsheng’s zero-expansion bricks, attributing this to the bricks’ excellent insulation and thermal stability.

Discover how our advanced refractory solutions can enhance your industrial furnace performance while reducing operating costs and downtime. Contact our technical team to discuss your project needs and receive a tailored consultation.

Request Your Custom Quote Now