In today's rapidly evolving industrial landscape, industries worldwide are facing increasingly stringent requirements for refractory materials used in high-temperature environments. As processes push operational temperatures to new heights, the reliability, durability, and efficiency of refractory bricks directly impact productivity and cost-effectiveness. This global demand has highlighted the need for advanced materials that can sustain extreme thermal stresses, provide excellent insulation, and offer long-term service life. Addressing these challenges effectively translates into reduced downtime, lower energy consumption, and improved product quality.

Among industry leaders, Zhengzhou Rongsheng Refractory Materials Co., Ltd. stands out as a pioneer specializing in manufacturing premium fused corundum bricks. Leveraging decades of expertise and cutting-edge production techniques, they cater to over 70 countries, supporting demanding sectors such as metallurgy, glass manufacturing, petrochemical, and power generation. Their flagship product, the fused corundum brick, exemplifies state-of-the-art quality and performance designed specifically to meet the rigors of high-temperature operations.

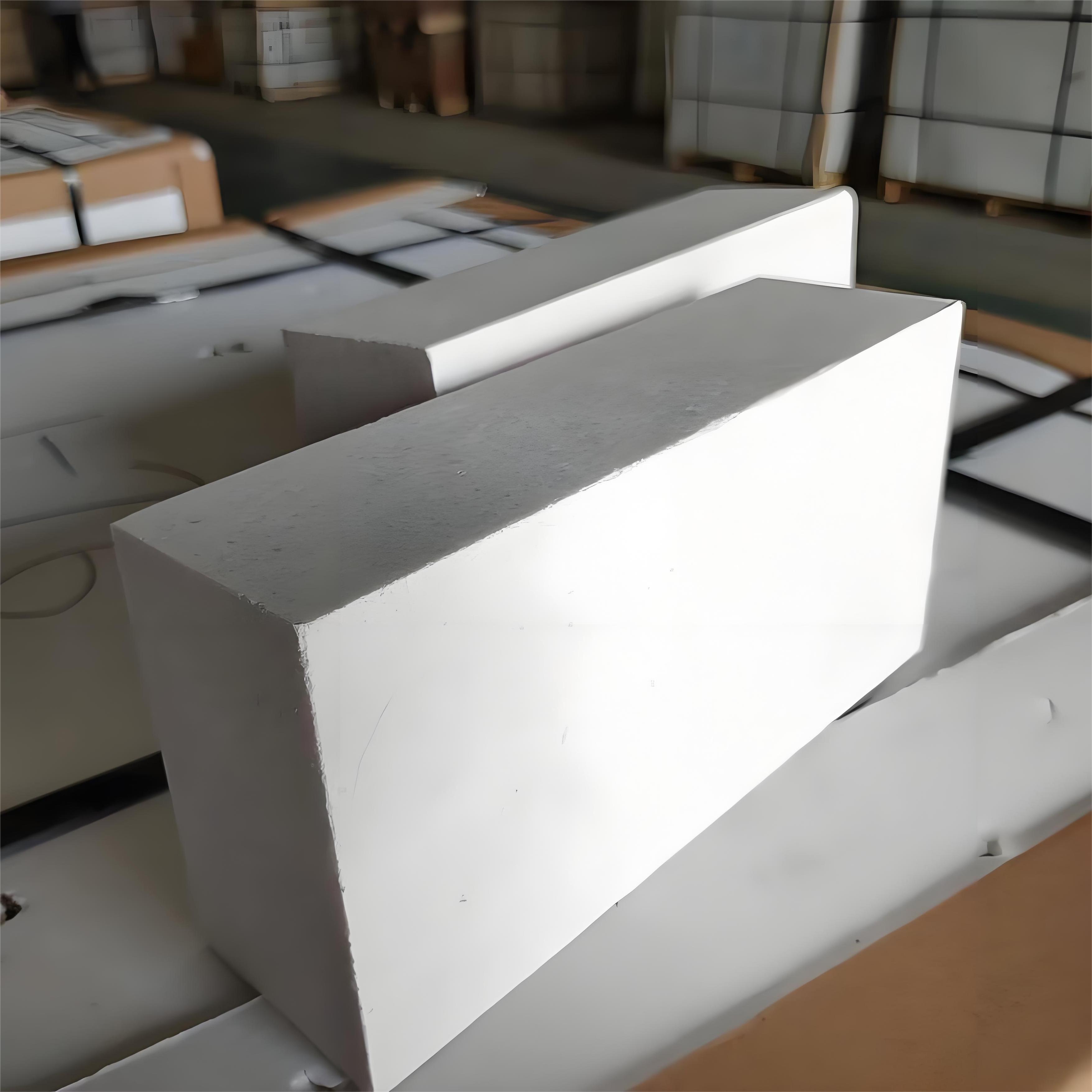

Fused Corundum Bricks for Glass Furnace" style="max-width: 100%; height: auto; border-radius: 8px; box-shadow: 0 0 10px rgba(0,0,0,0.1);">

Fused Corundum Bricks for Glass Furnace" style="max-width: 100%; height: auto; border-radius: 8px; box-shadow: 0 0 10px rgba(0,0,0,0.1);">

The fused corundum bricks by Zhengzhou Rongsheng are manufactured using advanced processes including isostatic pressing and high-temperature sintering techniques perfected over years of R&D. This ensures uniform density, minimal pores, and exceptional microstructural integrity. Strict quality control regimes are in place, from raw material sourcing to final inspection, guaranteeing that every brick meets international standards. In fact, these bricks comply with ISO 9001 quality management systems and have secured certifications such as CE and TÜV, underpinning their global credibility.

Key performance attributes include a refractoriness exceeding 1780°C, remarkable resistance to thermal shock exceeding 20 cycles (measured by the standard ASTM C704), and a bulk density averaging 3.65 g/cm³. These characteristics translate into superior durability and reliability, critical for demanding furnace linings and high-temperature vessel applications.

| Feature | Zhengzhou Rongsheng Fused Corundum Brick | Conventional Fire Clay Brick |

|---|---|---|

| Maximum Service Temperature | >1780°C | ~1400°C |

| Thermal Shock Resistance (ASTM C704 cycles) | >20 | 8-10 |

| Thermal Conductivity (W/m·K) | ~3.0 (lower heat loss) | ~4.5 |

| Average Service Life | 3-4 years (industrial settings) | 1-2 years |

Choosing Zhengzhou Rongsheng's fused corundum bricks empowers industrial operators to confidently address challenges posed by extreme heat environments. Their excellent thermal shock resistance substantially reduces maintenance downtime caused by frequent furnace shutdowns and brick replacements. Additionally, superior heat insulation minimizes energy consumption, contributing to cost savings and greener operations.

For example, a leading glass manufacturing plant that adopted these fused corundum bricks reported a 15% reduction in energy costs and a furnace uptime increase of 25% within the first year. Such quantifiable improvements underscore the bricks’ value proposition as a strategic asset in high-temperature production lines.

Since its inception, Zhengzhou Rongsheng has maintained an unwavering commitment to quality, innovation, and client satisfaction. Their philosophy centers on delivering reliable products backed by comprehensive technical support and responsive customer service. Through continuous product improvements and adherence to international standards, the company has cultivated a trusted global reputation. Their widespread presence across industrial markets testifies to their leadership and the confidence clients place in their refractories.

In conclusion, this fused corundum brick represents the best choice for industries seeking superior high-temperature refractory solutions. Its advanced manufacturing, certified quality, and outstanding performance features combine to deliver unmatched value.

Have you experienced the benefits of advanced refractory bricks in your operations? Share your challenges or success stories with us in the comments below or reach out via our contact channels. Your insights help drive innovation and better solutions for the entire industry.